Categories

- Wire & Cable

- Multi-conductor & Signal Cable

- Battery Cable Assemblies

- Terminals and Connectors

- Electrical Parts

- Electrical Tools

- ID Products

- Wire Management

- Tape & Sealant

- Mounting Panels & Panel Blanks

Need Help?

Click HereGet a Business Account

Apply HereBattery Cable Assemblies

![]()

![]()

![]()

![]()

![]()

![]()

![]()

What are battery cable assemblies?

A battery cable assembly is a short run of battery cable with both ends terminated that is used to connect one or more batteries to an electrical system. They can be terminated with a variety of electrical connector types and covered with protective boots to handle just about any application. They can range in length but are usually found in lengths between twelve inches and forty-eight inches. Pacer manufactures battery cable assemblies in the most common gauges, ranging from four gauge (4 AWG) to four aught (4/0 AWG). A high-quality assembly is a must in any electrical system with a harsh environment. For example, in the marine environment your batteries and cables will be exposed to vibration, moisture, corrosion, and other elemental hazards. When an assembly is built with longevity in mind, it is built to handle the harshest environmental conditions. This is our goal and our mindset when it comes to manufacturing each battery cable assembly.

*Important Note: This product is made to order and cannot be returned or refunded. Due to increased demand, please allow extra time for processing.*

Where are battery cable assemblies implemented?

Battery cable assemblies are implemented in applications where an electrical system needs to be connected to a battery or series of batteries. The first thing to look for is damage to the insulation or conductors on your current connection. Look for faded cable insulation, cracked cable insulation, or even burnt cable insulation. If you wanted to make your own assemblies, we offer the proper tools, lugs, battery cable, and heat shrink that you would need. Let us take a look at how our assemblies are built.

How are our battery cable assemblies built?

Pacer manufactures all its battery cable assemblies in-house in the USA to ensure the highest level of quality. We start by using our flexible and durable marine cable. This marine cable is designed to handle the toughest conditions out there. Next, we use a precision cut and strip machine for repeatable and accurate cuts. Once we have our cable ready, we use a state-of-the-art hydraulic-pneumatic crimper to create a superior gas-tight crimp. We use the highest quality crimp connectors to get superior connections. This crimp is another step to ensure the longest-lasting cable we can produce. At the last step, we add epoxy-lined heat shrink for an extra level of protection. The heat shrink seals out any moisture and helps to prevent corrosion from forming. This process gives you a moisture-proof and airtight connection built for longevity. We designed our assemblies to last for decades. In the end, you’ll be replacing your battery long before you replace our cable assemblies.

"We designed our assemblies to last for decades. In the end, you’ll be replacing your battery long before you replace our cables."

What kinds of lugs are used on Pacer's battery cable assemblies?

All Pacer battery cable assemblies are made with closed-end lugs or battery posts to eliminate the possibility of moisture intrusion. Both styles of connectors achieve this easily as they are built to be seamless. Each lug is made from 99.9% copper, which is then tinned to eliminate the chances of corrosion. Our battery posts are made from 131 contact copper that has been tin plated. This ensures that you not only get the strongest connection possible but that it is protected from exposure in the harshest marine conditions. By using high-quality crimp connectors, we ensure the longevity of the assembly.

Why does Pacer use epoxy-lined heat shrink?

Pacer utilizes epoxy-lined heat shrink for the simple reason that it offers the highest possible level of environmental protection. Let me explain: normal heat shrink constricts when heated, thereby reducing its diameter. When heat shrink is epoxy lined instead, that epoxy, when heated, melts and gets pushed out as the constriction occurs. This epoxy then cools and hardens, creating a superior seal that prevents moisture, oil, salt, acids, and other contaminants from damaging your electrical system. The bottom line is if you are using battery cable assemblies for marine applications, make sure that each connection point is secured with epoxy-lined heat shrink.

What types of terminations are on Pacer's battery cable assemblies?

Pacer's ever-expanding line of battery cable assemblies already includes the most common and most requested options. Our electrical wire connectors are perfect for use on assemblies. We currently offer our assemblies with either 3/8" lugs or 5/16" lugs on each end. If closed-end lugs are not what you're looking for, we also offer assemblies with a positive or negative post with a battery boot covering. These are available so that you can connect directly to the battery if desired or use our assembly for another connection point if needed. In the case where you get a positive or negative post with a boot, the lug will also come with a boot. Look below to get a clear idea of the terminations that you want on the ends of your assemblies. Another question that we receive is about what compliances our assemblies meet.

Lug

Lug with Boot

Post and Boot

What compliances do our battery cable assemblies meet?

Pacer aims for quality, and we prove it by not meeting one or two, but a multitude of compliances. We go as far as not only meeting compliances with our cables and connectors but also with the way in which we crimp. Look below to see the compliances and standards that our assemblies meet. Click on any icon to be taken to a detailed explanation of that compliance.

Pacer Battery Cable Assemblies

Pacer Crimping Process

How flexible are our battery cable assemblies?

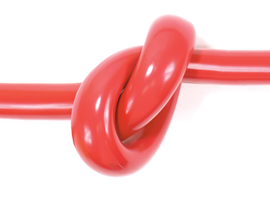

We do not recommend tying any cable into a knot as it can create a point where heat can build up.

Pacer battery cable assemblies are so flexible that they can easily be tied into a tight knot and then untied without compromising their strength or durability. How many other wire and cable manufacturers can say that their cable does that? The insulation is made from a proprietary blend of PVC that never uses regrind. Our unique blend focuses on durability, longevity, and flexibility. You will find that Pacer battery cable assemblies are much more flexible than your average everyday assemblies. This is just one of the many reasons you will find our battery cable assemblies implemented in so many locations.

What types of devices use our battery cable assemblies?

Their unique design of our assemblies makes them perfectly suited for harsh marine conditions. This ability to withstand harsh environments makes them perfect for automotive use as well. Hot rod enthusiasts have turned to Pacer for their battery assemblies. Think about that for a second. Someone building a hot rod muscle car is only going to put the highest quality materials into their project. Who do they turn to for those high-quality parts? Pacer. Aside from hot rods, you’ll also find our assemblies in golf carts and even industrial equipment. The bottom line is that our assemblies are so well built that they are versatile enough to be used across a wide range of industries.

| Wire Gauge | Cable Gauge |

|---|---|

| 4/0 AWG (Four Aught) | Black, Red, Yellow |

| 2/0 AWG (Two Aught) | Black, Red, Yellow |

| 1/0 AWG (One Aught) | Black, Red, Yellow |

| 1 AWG (One Gauge) | Black |

| 2 AWG (Two Gauge) | Black, Red, Yellow |

| 4 AWG (Four Gauge) | Black, Red |

Why choose Pacer for your battery cable assemblies?

We have invested nearly four decades into creating superior products that distinguish themselves from the competition. Over that time, we have mastered our craft and honed the things that matter when creating quality products. We have built a reputation as a trusted U.S. manufacturer that some of the world’s largest boat builders turn to. Each Pacer assembly is designed with flexibility, durability, and longevity in mind.

*This page was updated on 1/30/2025*