Categories

- Wire & Cable

- Multi-conductor & Signal Cable

- Battery Cable Assemblies

- Terminals and Connectors

- Electrical Parts

- Electrical Tools

- ID Products

- Wire Management

- Tape & Sealant

- Mounting Panels & Panel Blanks

Need Help?

Click HereGet a Business Account

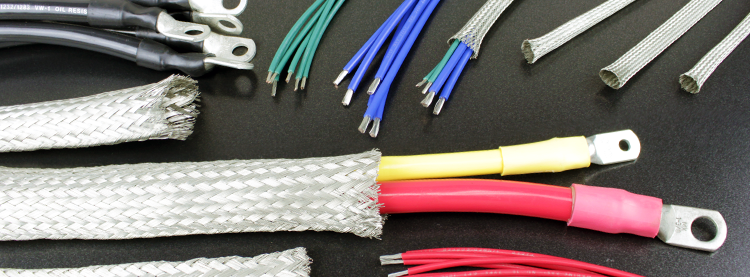

Apply HereTinned Copper Braid

What is tinned copper braid?

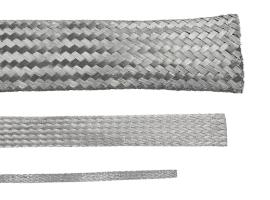

Tinned copper braid is a type of multiconductor cable that is a tight weave of soft-drawn tinned copper wire. Originally constructed as a tube, it is rolled flat, creating a specific width. Why would you use tinned copper braid cable? There are a variety of reasons to use this type of cable, such as it is excellent for use in shielding short runs of wire, is easily terminated, and is ideal for use as a low-impedance ground path. Braided cable is ideal for a multitude of jobs.

Is this type of cable durable in harsh environments? Yes, it is. The tinned copper conductors and woven construction make it flexible. This flexibility gives braided cable superb durability against harsh marine conditions such as vibration and flux. Now that you have a better understanding of what tinned copper braid is, let us look at what types we offer.

"It is excellent for use in shielding short runs of wire, is easily terminated, and is ideal as a low-impedance ground path."

What types are available?

Pacer carries tinned copper braid cable in a variety of sizes to accommodate a multitude of applications. We currently offer tinned copper braid in 1/8” (3.175mm), 1/4” (6.35mm), 3/8” (9.525mm), 1/2” (12.7mm), 5/8” (15.875mm), 3/4” (19.05mm), 1” (25.4mm), and 1 1/2” (38.1mm), diameters so that you can find the size that is best suited for your needs. It is important to note that while the stranding of our tinned copper braid mostly stays the same regardless of diameter, the construction differs. That is to say that the 1/8” tinned copper braid had a construction of 24x3x36, whereas the 1 ½” diameter has a construction of 48x11x30. For a more detailed understanding of construction and tinned copper braid AWG, click here to see the spec sheet. Now that we have covered what types are available, we can look at the features that this type of multiconductor cable offers.

![]()

Does it offer any features?

Tinned copper braid offers several important features, such as high flexibility, easy termination, corrosion resistance, a multitude of sizes, and even diverse applications. This goes to show just how useful tinned copper braid really is. The fact that this cable is made from soft-drawn tinned copper ensures that it can offer high conductivity while handling tough marine conditions. Additionally, think about how important flexibility is in a marine environment. Not only with the installation process but also with handling the constant vibration and flux that are found in marine conditions. It is essential to use a cable that is built with flexibility in mind. This is one of the main factors that makes tinned copper braid ideal for a range of applications.

![]()

High

Flexibility

![]()

Easily Terminated

![]()

Corrosion Resistant

![]()

Multiple

Sizes

![]()

Diverse Applications

Where are these products implemented?

Tinned copper braid is implemented in many industries.

Tinned copper braid is implemented in applications that require a certain level of protection for wires they envelop. It does this by completely covering the wire and acting as a barrier. In addition, they offer protection against ignition interference, but we will discuss that in greater detail further down this page. The bottom line is that tinned copper braid is implemented, for the most part, in the protection of wires it encases. When dealing with tinned copper braid, you won't need fancy connectors or terminals. All you really need are the proper tools.

Which applications is tinned copper braid made for?

Tinned copper braid is ideal for applications such as shielding short wire runs, creating a low-resistance path, and protecting interior wires. Additionally, tinned copper braid can be used to eliminate ignition interference and can be used as a grounding bonding strap. With all these diverse applications, you can see why so many people turn to tinned copper braid. It is one of the most versatile types of multiconductor cable available. Couple this with the fact that it can resist corrosion due to its tinned copper coating, and you have a superior type of cable. One question we often receive about tinned copper braid is about selecting the correct size.

How do I select the correct size for my project?

When selecting the correct size of tinned copper braid for your project, the first thing to consider is the application. If you are protecting interior wires, you will likely want a different size than if you are creating a low-resistance path. So, the answer is there is no easy answer. The bottom line is that the size you need will depend on several factors, such as the intended purpose and the environment where it will be installed. For example, if you are planning to simply protect a few smaller gauge wires, then 1/8” or 1/4” would be appropriate. The only time the diameter is not much of an issue is when tinned copper braid is used as a grounding bonding strap. If you are having trouble selecting the correct size or just have a question about tinned copper braid, contact a Pacer expert today and let us help.

What industries use tinned copper braid?

Tinned copper braid is found in multiple industries, such as the marine industry, the aviation industry, heavy equipment manufacturing, and even at industrial locations. It is chosen for its multiple uses as well as its flexibility and overall longevity. People know that they need a cable that can handle tough conditions with ease. There is a reason that you will find tinned copper braid in so many different industries. It is because people know that they can trust it to perform when they need it to.

![]()

![]()

![]()

![]()

*This page was updated on 1/30/2025*