Choosing the Right Tool

Posted by Pacer on 28th Mar 2019

*This Article was published on 3/28/2019 and was updated 9/26/2022*

Learn the difference between the most common types of tools and how to choose the right one.

Anyone who has ever worked in a machine shop, on a car, or any electrical system, can tell you the importance of using the correct tools. Not only the correct tools but quality tools. When you utilize quality tools you cut down on the time spent, and increase the quality and quantity of output.

So just how important is it to use the proper tool? Extremely important. Regardless of the task at hand, having the proper tools will help ensure that the job is done correctly. Tools also make getting the job done easier. What happens when you use the wrong tool for a job? When you use the wrong tool, you end up spending time fighting to get it to do something it's not designed to. Each tool is built around a specific purpose, and misuse could damage the product or the tool itself. With that out of the way let's take a look at some of the more commonly found electrical tools. You'll usually find these when someone is working with wire and cable.

Common Types of Tools

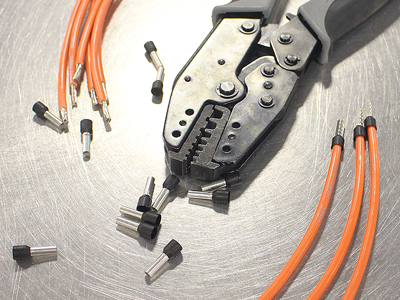

When dealing with wires in an electrical system, one of the most important aspects is the wire crimp. What is a crimp? A crimp is the way in which the terminal is compressed on to the wire. Each wire needs to connect to something; and terminals are used to make those connections. In turn, each terminal is attached to the end of the wire. That attachment usually occurs as a crimp. There are other methods, however, in most cases, crimping is the preferred method. This is due to the fact that you can crimp a terminal in the field, and complete it rapidly. Universally, crimping is a trusted reliable way to secure a terminal to the end of a wire or cable. Crimpers are known for their ease of use and repeatable accurate performance. Some such as the VTTR-50 offer a ratcheting motion. This ensures a successful crimp with each complete compression. Crimp connectors are just one of many electrical connector types. Using the right tools ensures that your electrical wire connectors get the proper crimp.

- Ideal for Field Service

- Easy to Use

- Proven Reliability

- Multiple Applications

In order to make transportation and storage easier; wire and cable both come on spools. These spools can easily hold 1,000 feet in length or more. To get the right amount of wire or cable, you will need to cut it at the correct length. The right tools make this a simple task. We all know cutting through metal requires a lot of force. Did you know using the wrong tool can damage the insulation, conductor, or even the tool itself? This can lead to an increased chance of corrosion, or loss of conductivity. Wire cutters are designed to cut through a wire with as little effort as possible. Cable cutters, especially ratcheting cable cutters, can make cutting 4/0 AWG an easy task. The ratcheting action makes cuts consistent and almost effortless.

- Protects Insulation

- Consistent Cuts

- Repeatable Accuracy

- Near Effortless Cutting

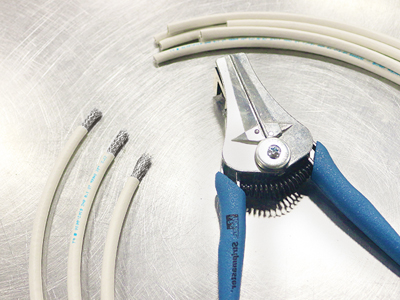

"These tools are known for their repeatable accurate cuts."

Before connecting a terminal to a wire or cable, you must first expose a portion of metal on that end. This is where wire strippers come into play during electrical jobs. Simply cutting and pulling the insulation off a wire; will likely damage the conductor or the insulation. This can result in a loss of conductivity and in some cases even a loss of part of the conductor. You could also damage the insulation which can lead to an increased risk for corrosion. Think about the harsh environments that Pacer wire and cable exist in. These small errors can lead to long term damage. Why? Because the wrong tool was used. Wire strippers used correctly; on the appropriate size wire will remove the correct length of insulation every time. Now you don't have to worry about damage to the insulation or the conductor. Not to mention the way the tools are designed make the job that much easier. Consider having to rewire a panel. You could be dealing with a lot of wire. Make the job easier and ensure it's done properly but using the right tools.

- Protects Internal Conductors

- Multiple Blade Settings

- Simple to Use

- Works on Multiple Wire Sizes

One advantage wire has over cable is its smaller diameter. This means it weighs less; and it is easier to cut, bend, and manipulate. Wire strippers/cutters are built to be a multi-use tool. They are designed to cut the wire easily, and then strip the wire using a different part of the same tool. Conveniently, they are made to handle multiple sizes of wire. One of the main features of these tools is their "teeth" that are sized to handle a particular gauge. The tip of these types of tools is often shaped in such a way so they can be used as needle-nose pliers. As a multi-use tool, the entire design is based on convenience. You'll find this in the pocket of just about everybody who works around wire on a consistent basis. That goes to show just how useful they are.

- Ideal for Field Service

- Easy to Use

- Proven Reliability

- Multiple Applications

Certain companies use their own proprietary terminals and connectors. Deutsch products have been developed for industrial use. Designed for harsh conditions, these connectors are built for longevity and sustainability. Since the parent company developed it's own style of terminal, they needed specific tools to get the terminals onto the wire. With this in mind, they built the Deutsch line of tools for specificity, reliability, and re-usability. Their tools are as high-quality as their terminals and connectors. This means you get the correct pressure crimp in the proper location on the terminal each and every time. Deutsch pins and sockets are just one of the many types of crimp connectors you'll encounter. Electrical connectors come in a range of styles to handle just about any job.

VT-HDT-1561

- Built for Pins & Sockets

- Made for Longevity

- Multiple Settings

- Ideal for Field Service

"This means you get the correct pressure crimp in the proper location on the terminal each and every time."

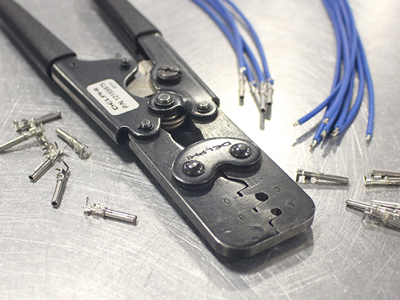

Delphi, also known as Aptiv, is another example of a company-specific terminal and tool-set. Commonly found in the automotive industry, Delphi products are meant for long-term use in harsh environments. They can handle more extreme temperatures than other, similar terminals. In many instances, they are used in the engine bays of cars and trucks. This shows that they are made to handle high levels of heat. For Delphi terminals to work properly, they must be used with Delphi's line of tools. Often times, many of the terminals come with protective seals that are added during the crimping process. These seals that cover the wire connectors add an extra level of protection to the connection guaranteeing a longer life.

- Designed for Repeatability

- One-hand Use

- Perfect for Field Service

- Highly Durable

These may be the most versatile tools on this list. Heat tools are used for a range of tasks. These tasks include; shrinking heat shrink, soldering, repairing vinyl, pinpointing heat, spot drying, and more. One great thing about heat tools is that they come in a wide range of sizes and styles. Some are so large they can be mounted to a table while others are small enough to fit into your pocket. Depending on the style you get, there may be a variety of interchangeable pieces that can increase the capabilities of the tool. These tools also carry the highest risk of accidental injury. Please use caution when handling any heat tool as some can get as hot as 1300°F.

- Range of Applications

- Multiple Settings

- Up to 1300°F

- Easy to Use

When bundling wires or surface mounting objects, cable ties are an invaluable resource. Depending on the type of cable tie you use, whether it be nylon or steel, you will need different tools to use them properly. The proper tools guarantee the correct tension and the removal of any excess length. With cable ties, tension is an important aspect. Too much, the tie breaks or damages it's contents. Too little, and the contents are not secure. To ensure the correct tension, as well as a clean presentation, each style of cable tie has corresponding tools. Stainless steel cable ties can be used with manual or ratcheting tools depending on your personal preference.

- Unique Applications

- Multiple Settings

- Easily Adjustable

- Ideal for Field Service

"The proper tools guarantee the correct tension and the removal of any excess length."

Coaxial and Category cables use unique terminals not commonly found on other types of cable. These terminals often involve plug type or twist type ends. Coaxial and category cable terminals cannot be attached with normal tools like the ones listed above. Instead, these types of terminals often require compression tools or specially designed installation tools. Coaxial connectors almost always require a compression tool to be properly installed. This way they create a tight connection that can withstand high force before damage occurs. Category cable plugs also need a highly specific tool in order to get the job done the correct way. This way the terminals are secured in a way that best suits the wire type and application.

- Easy to Use

- Simple to Adjust

- One hand Action

- Reliable Results

Tools in this category are highly specific or are not easily categorized like the tool types above. Specialty tools include; ferrule crimpers, voltage testers, multimeters, and similar items. Often they perform a unique or custom function. Many of these tools offer a single purpose. With specialty tools, you find unique equipment that offer abilities that other tools cannot handle. As always, it is best to pick to the right tool for the job especially if it requires a specialty tool. When you cannot find the tool to complete a specific task, sometimes it's best to look for specialty tools.

- Specific Applications

- Reliable Accuracy

- Unique Functions

- Perfect for Field Service

After looking at the different types of tools common to working with wire and cable, you can clearly see the need for specific types. Each tool completes a unique task that could not be done properly otherwise. Pay attention to the type of tool you select for a given task. Having the proper knowledge of how to use the tool is invaluable as it will ensure high-quality output and saved time. Have a job and don't know which tool to use? Contact a Pacer expert and let us help.