Over 1000 Different Types of Wire and Cable

Posted by Pacer on 17th Jan 2019

Over 1,000 Different Types of Wire and Cable

Follow along as we take a look at some of the most common types of wire and cable

When it comes to wire and cable, there is no one size fits all. It’s actually quite the opposite. Wire and cable are designed to be used for certain applications in certain conditions. Change one of those factors and you may need to change the style or type of wire and cable you are using. This specificity of wire and cable means that any job you can think of, there’s a wire or a cable out there designed with that job in mind. Having a basic understanding of some of the more common types of wire and cable can lead to less hassle and fewer headaches when trying to handle your next project. Let’s take a look at some of the most common types available. This list is by no means comprehensive; however, it does touch on the more common types of wire and cable that you’re are likely to encounter.

What is wire? How is it different from cable?

Now, before we get started, it’s important that you understand what we mean when we say wire and cable. The terms wire and cable can actually be slightly ambiguous. For our discussion, we will be referring to flexible strands of metal that are used to transmit electricity or various types of signals. So basically, you have this strand of metal that can vary in diameter. The thicker it is, the more electricity or signal it can carry. The problem arises when you start to get too thick in diameter. When this happens, you begin to lose flexibility and durability as it will be damaged by stress more easily. To circumvent this problem, several smaller wires are bundled together. We call these bundles “ropes”. Let’s look at a few examples of wire sizes to give you a better idea.

"Multiple ropes of fine stranded copper allow wire and cable to bend and flex."

If we used a 30-gauge primary wire, it would be made up of a

single strand of metal. A 16-gauge primary wire, on the other hand, would

contain one rope made from 24 strands of 30-gauge wire. A 1-gauge cable would

be made up of 19 ropes with each rope containing 44 strands of 30-gauge wire.

Notice I said cable there? That’s because cable is made up of multiple ropes.

So, if you have a single strand of metal or a single rope made from single

strands, then you have wire. Once you get into multiple ropes, you have

officially entered cable territory. Confused yet? Don't worry, there isn't a

test the end. Rope stranding offers greater flexibility which is essential in

marine wiring. Multiple ropes of fine stranded copper allow wire and cable to

bend and flex. Normally, this flexing could cause damage to the copper or

reduce its conductivity.

So now you know the difference between wire and cable, let’s get back the various styles we’ll be investigating.

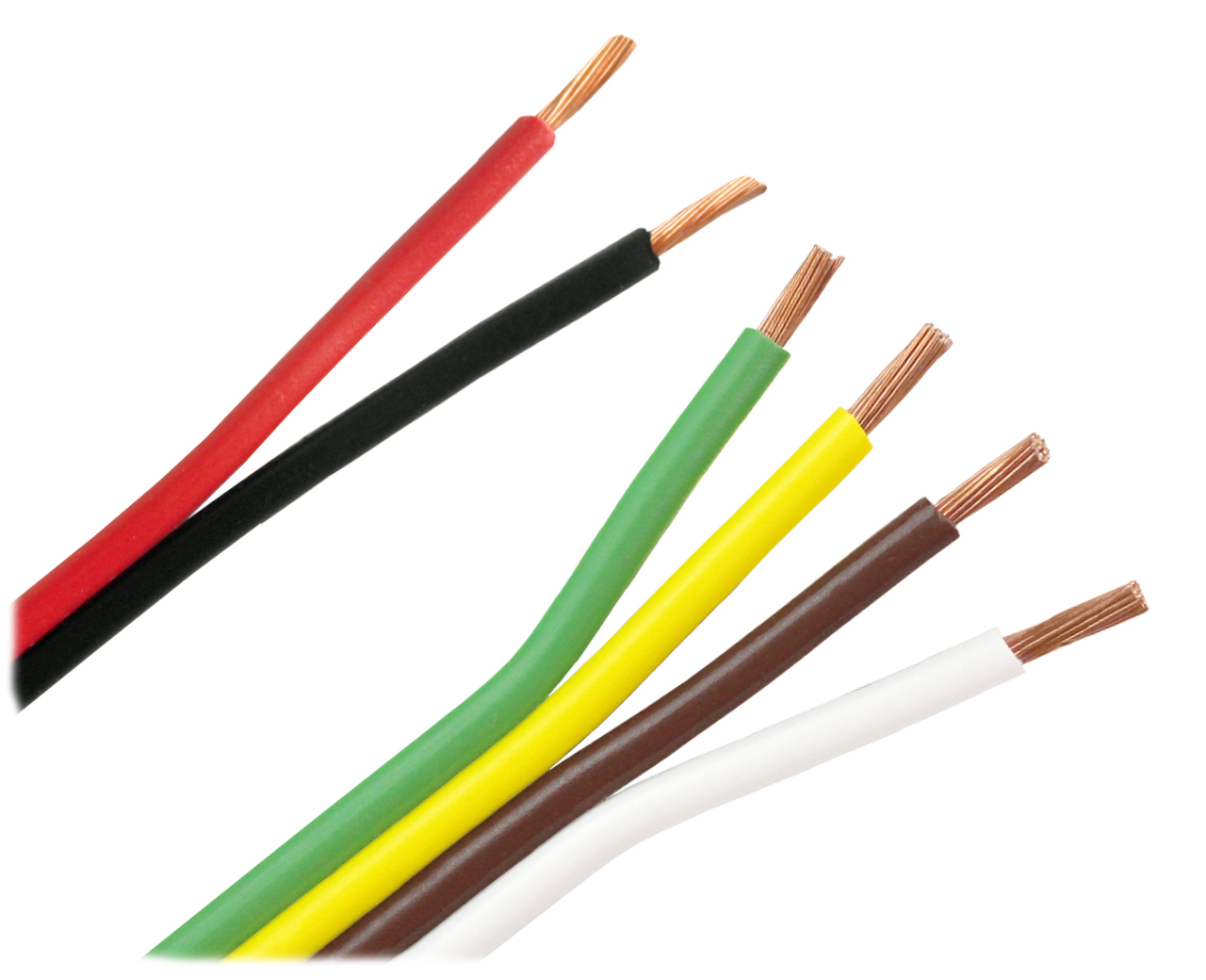

Primary Wire - also called Marine Wire

The most common type of wire you’ll find is primary wire. It is in everything from your car to your boat. Many household appliances and even outdoor electrical tools use primary wire. It is an insulated stranded copper wire. In many cases, especially marine use, the copper is tinned. This serves to not only resist corrosion but to strengthen the natural properties of the copper. Primary wire is commonly measured from 40 gauge to 4 gauge although different governing bodies may follow a different range. Pacer manufactures primary wire (marine wire) in-house to ensure the highest level of quality. We offer our wire from 18 gauge to 8 gauge as these are the most likely sizes to serve our client base. Our wire is constructed from Type 3 Class K tinned copper wire. It is then insulated in a proprietary insulation. This insulation is built to enhance the longevity and durability of the wire.

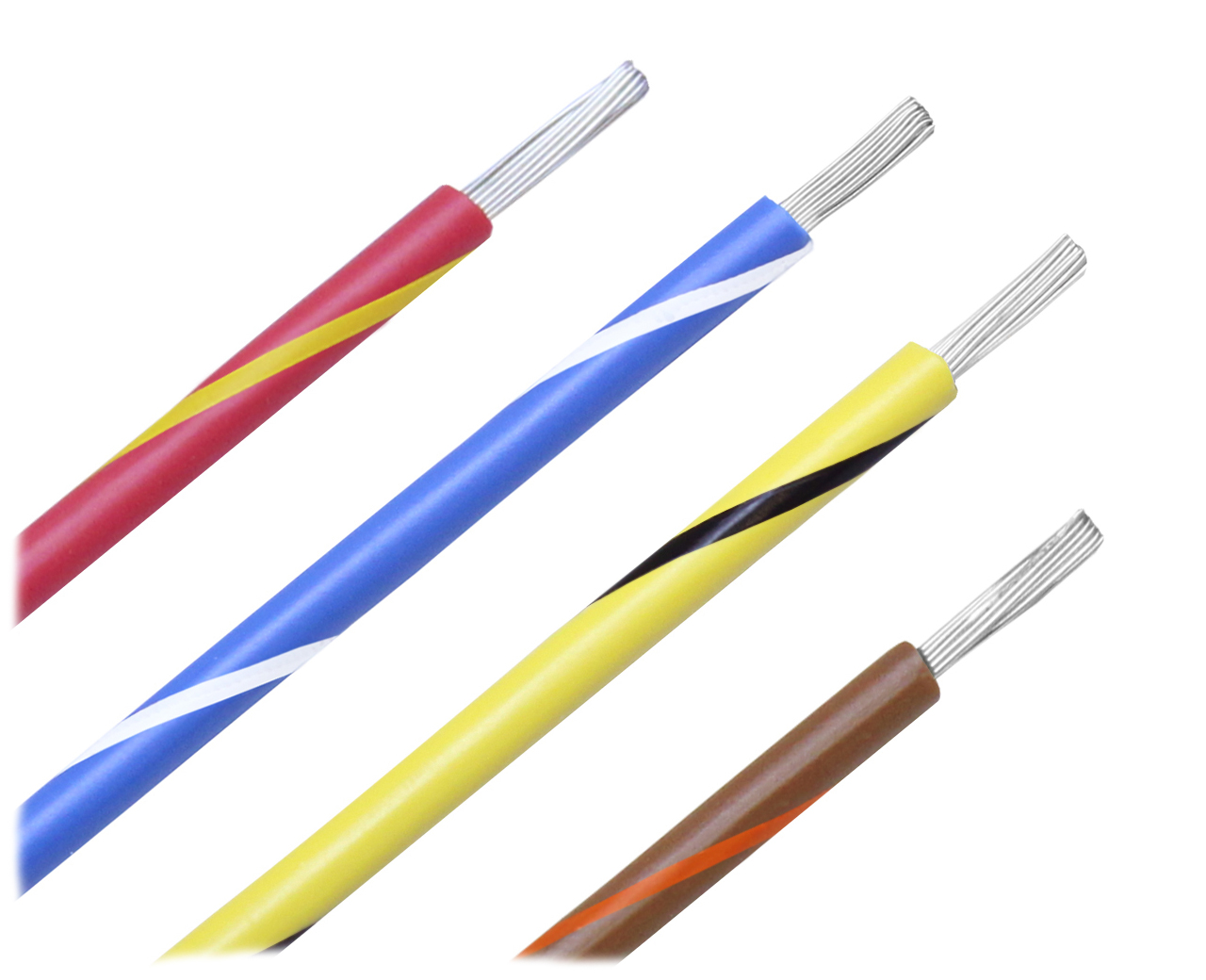

Striped Marine Wire

Often times an electrical device or piece of electrical equipment will require a multitude of wires to function properly. How do you tell all the wires apart? Well, there is a color code that manufacturers follow which standardizes the intended purpose of a given wire. Sounds simple right? Well, what about when you get into thirty, fifty or even one hundred wires? How would you tell all of those apart? It’s not cost effective to produce one hundred insulation color varieties. The solution? Striping. Striping allows a wire to be wrapped in one or more color bands to make identification easier. In this way, you could literally have one hundred unique wires that were all easily identifiable. This would make any changes or maintenance to the system much easier and faster. Next time you need to handle a job that requires a multitude of wires, keep striped marine wire in mind.

"When it comes to marine usage, battery cable needs to be flexible and durable."

Battery Cable

Battery cable is often used to connect, you guessed it, batteries. That is not the only use mind you, but it is where it gets its name after all. Other uses include connecting a generator to a switch, starter or ground, windlass, inverter or in any high amperage equipment. Battery cable needs to offer a high level of protection from harsh environments. Whether it’s used on a boat or in an automobile, it will need to be able to withstand excessive heat and vibration. Pacer battery cable is designed specifically to handle the harshest marine conditions. Built from fine stranded Class K tinned copper it is ideal for marine use. When it comes to marine usage, battery cable needs to be flexible and durable. In a marine environment there are many sharp turns and there is the constant vibration and flex that must be considered. Pacer’s battery cable carries a proprietary insulation that is built to enhance longevity and durability. It is so strong in fact that it is resistant to acid, alkali, abrasion, flame, oil, gasoline and moisture making it the perfect choice for marine usage. This cable is so tough that it will outlive the batteries you connect it to. We offer marine battery cable from 6 gauge to 4/0 AWG in order to meet any marine needs.

Battery Cable Assemblies

While we're looking at battery cable, it’s important to consider battery cable assemblies. These are premade assemblies custom built for each customer. If you made your own battery cable assemblies, it would take expensive equipment and time most of us just don’t have. Pacer battery cable assemblies are built in-house to ensure perfection each and every time. We use a precision machine that cuts and strips in a repeatable, accurate method. To make it even better, our hydraulic-pneumatic crimper creates an unbeatable gas tight crimp. Add epoxy lined heat shrink and you have the highest quality battery cable assemblies available on the market. Think about it, stocking battery cable assemblies is expensive. Just like owning the equipment to make them yourself. It makes sense to purchase pre-made cables to get what you want when you need it.

Boat Cable

Round Boat Cable

Triplex Boat Cable

Duplex Boat Cable

Boat cable comes in a variety of styles each one serving a different purpose. Commonly, you will find round, duplex and triplex boat cable are the most often used. All three are manufactured to handle the marine environment. This means that they can handle the stress of vibration and flexing over extended periods of time. When wiring a boat, many wires and cables will need to pass through tight spaces such as the hull. In these spaces, there may be a multitude of sharp turns so using a flexible cable is an absolute necessity. Many wire and cable manufacturers will simply slide the jacket over the conductors and ship it out like that. The problem with this method of manufacturing is that there is now space inside the cable for moisture to accumulate. This will wear the cable down faster and lead to corrosion. Look for boat cable where the outer jacket has been extruded so that there is no space for moisture to build up.

Round Boat Cable

As stated above, this cable is designed for routing through tight spaces where there may be sharp turns. Think about it, if you use a flat cable, how do you get it to bend in all directions? You don’t. That’s why you want to use round boat cable for any tight spaces where you may need to bend the cable in a totally different direction. By using cable designed for flexibility, you make the installation process simpler, easier and faster. Other cables will give you a very limited range of motion but not round boat cable. You could literally tie this cable in a knot if you wanted to, but we strongly recommend against that. Since this cable is going to subjected to a long-term tough environment it must be the strongest it can be. That's why this cable offers all of the resistances you would need for a marine cable. This type of cable is ideal for use with T-tops, sailing spars and poling platforms.

Triplex Boat Cable

This is a type of boat cable is designed for power specific applications. Whether you need to wire 120V AC, 230V AC or even 240V AC, triplex is the cable for the job. You can identify the intended purpose and power transfer capabilities just by looking at the outer jacket. If the jacket is white, then it is rated for US 120V AC wiring. The internal conductors would be white, green and black. When the jacket is tan, then the cable is built for European 230V AC wiring. In this case, the internal wires would be blue, green with a yellow stripe and brown. Finally, if the jacket is blue, then the cable is built for US 240V AC wiring. The internal conductors would be red, green and black. See how easy this is? Just like the other types mentioned above, this cable is built for longevity and flexibility. Can you guess why? That’s right. Tight spaces and harsh conditions.

Duplex Boat Cable

In many electrical systems, a durable cable is required to handle harsh conditions. This is where duplex boat cable comes in. This multi-purpose cable is ideal for internal wiring on boats. Another common purpose is for use connecting transformers in AC systems. You may notice that although the jacket of this cable stays white, the color of print varies from black to silver, to blue. This is meant to identify the color of the conductors inside the cable as well as its intended purpose. Black print means that the conductors inside are black and white. This is considered the “standard” duplex cable. If the print is silver, then the conductors inside are red and black. This cable is considered “DC” duplex cable. When the print is blue, the conductors inside are red and yellow. This type of cable is considered “Safety” duplex cable. This color coded system makes identification a simple task for anyone involved. This is just one of the ways we make the installation process as easy as possible. Now, when you see duplex cable on a boat, you’ll be able to identify the internal conductors with just a glance.

Speaker Wire

When dealing with home theaters, stereo speakers, digital audio and the like, you want to use a type of wire designed specifically for the job. This is where speaker wire comes into play. This wire is usually designed with clear installation to make conductor identification easier. The main concern when using speaker wire is selecting the proper gauge. How do you do that? Well, the easiest way is to figure out how long the wire needs to be to reach both points. Be sure to add a few extra feet in case of error and a little slack is nice. Once you know your distance, it’s not too difficult to determine the correct gauge. Let’s say you’re running wire 15 feet to an 8-ohm speaker, then 16 gauge would be a safe bet. But what if you need to go over 50 feet? In this case, you may want to use 14 gauge or even a 12 gauge. One important note about speaker wire is that it is not built to be used in walls.

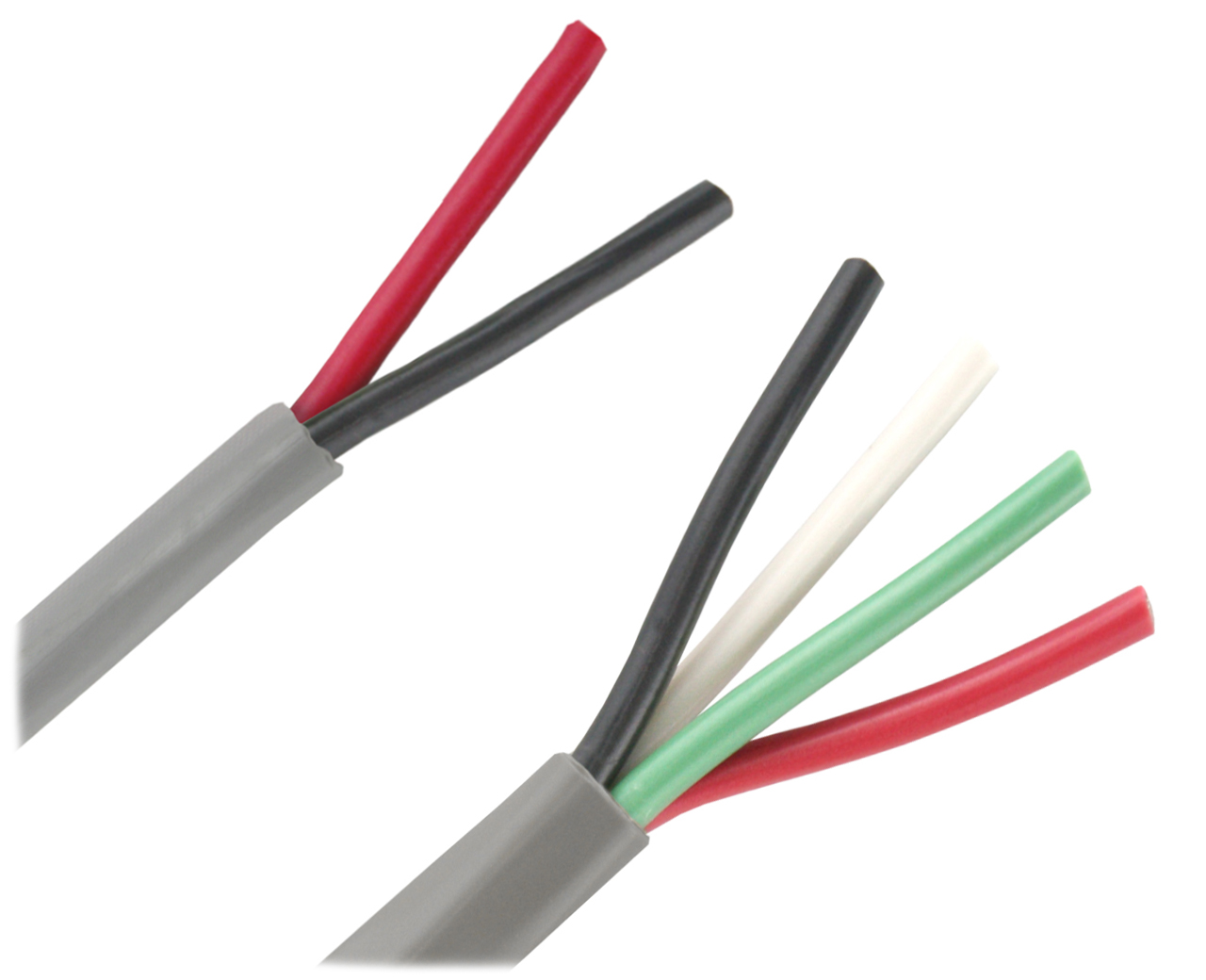

Multiconductor Cable

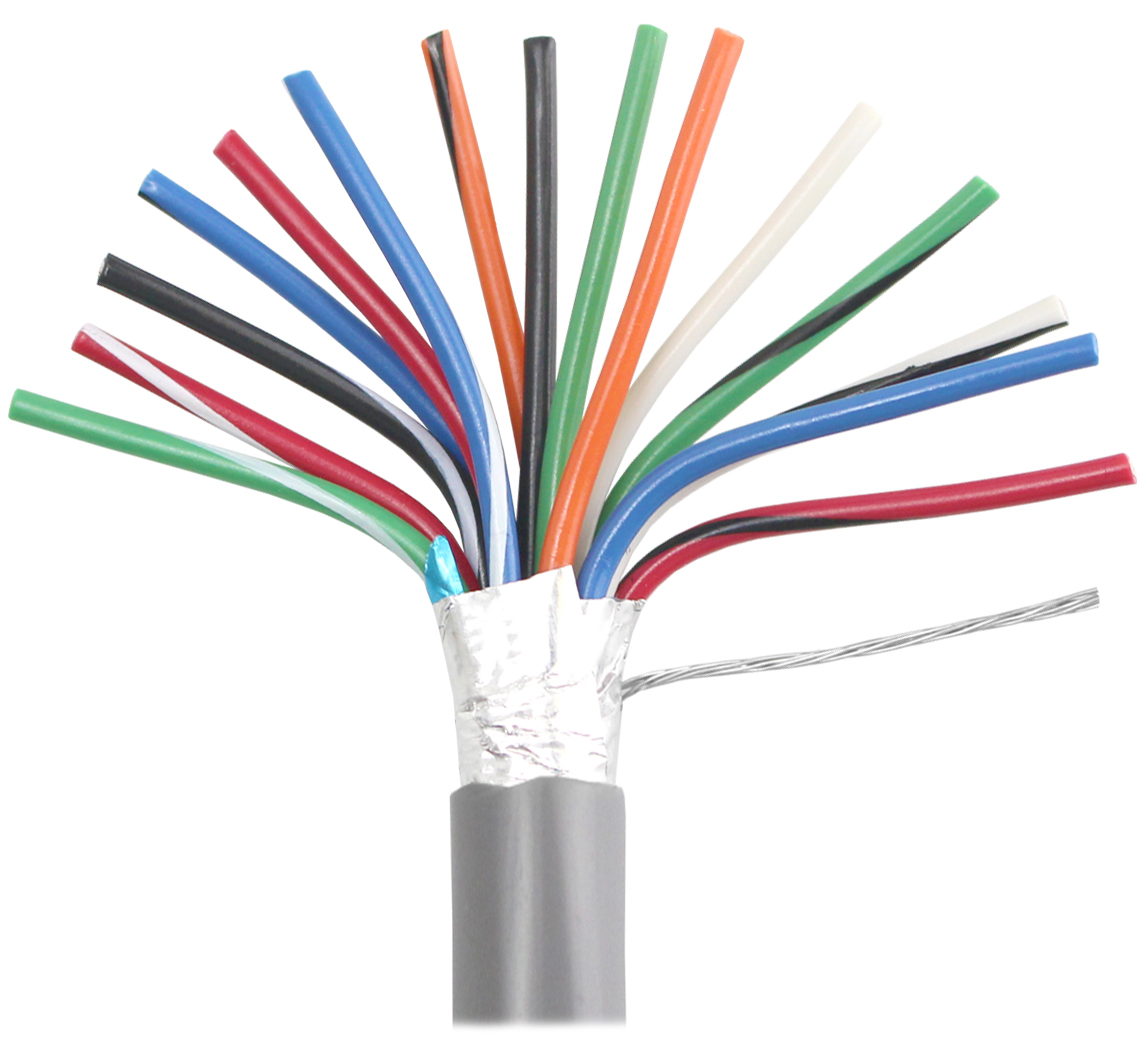

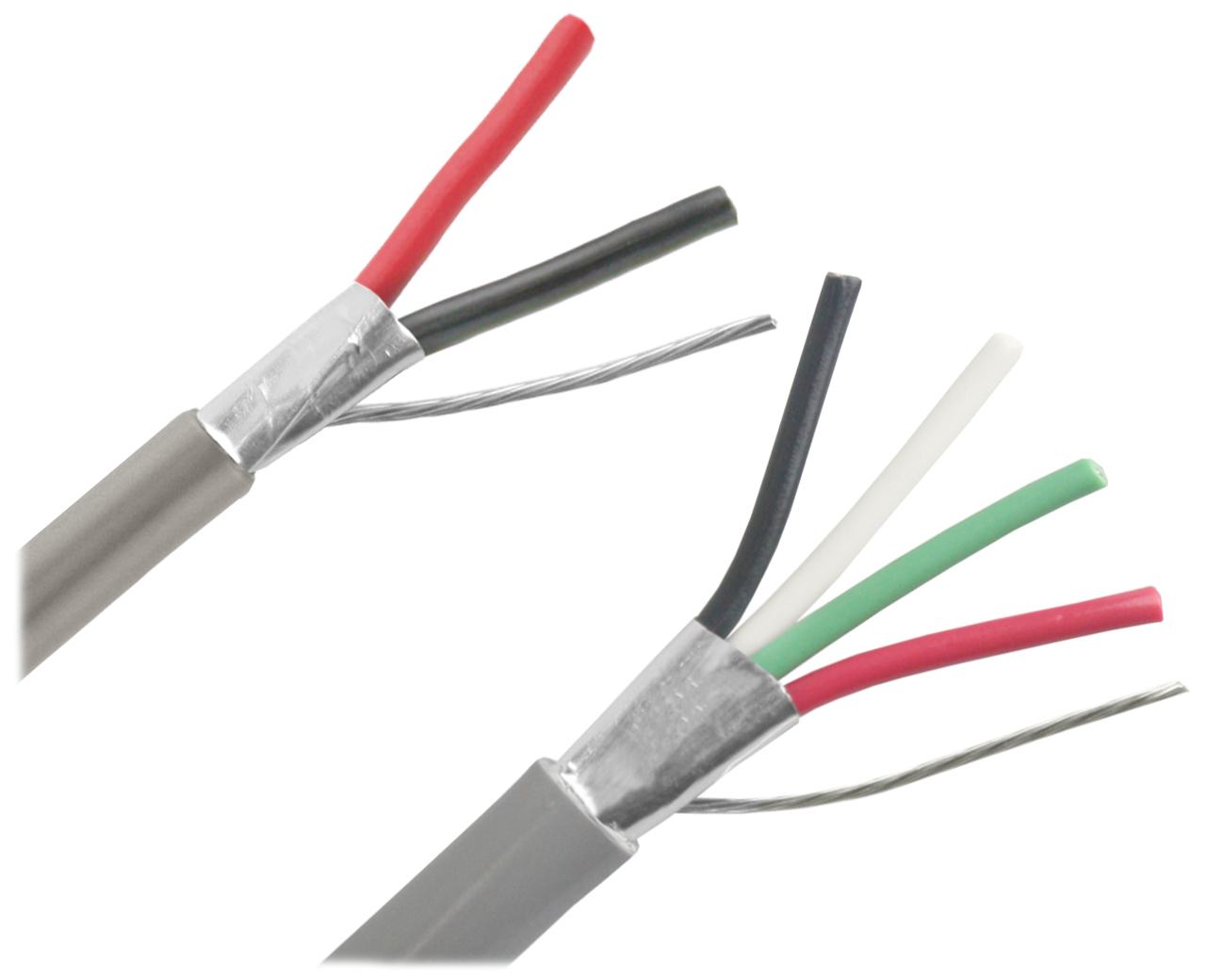

Shielded Multi Conductor

Unshielded Multi Conductor

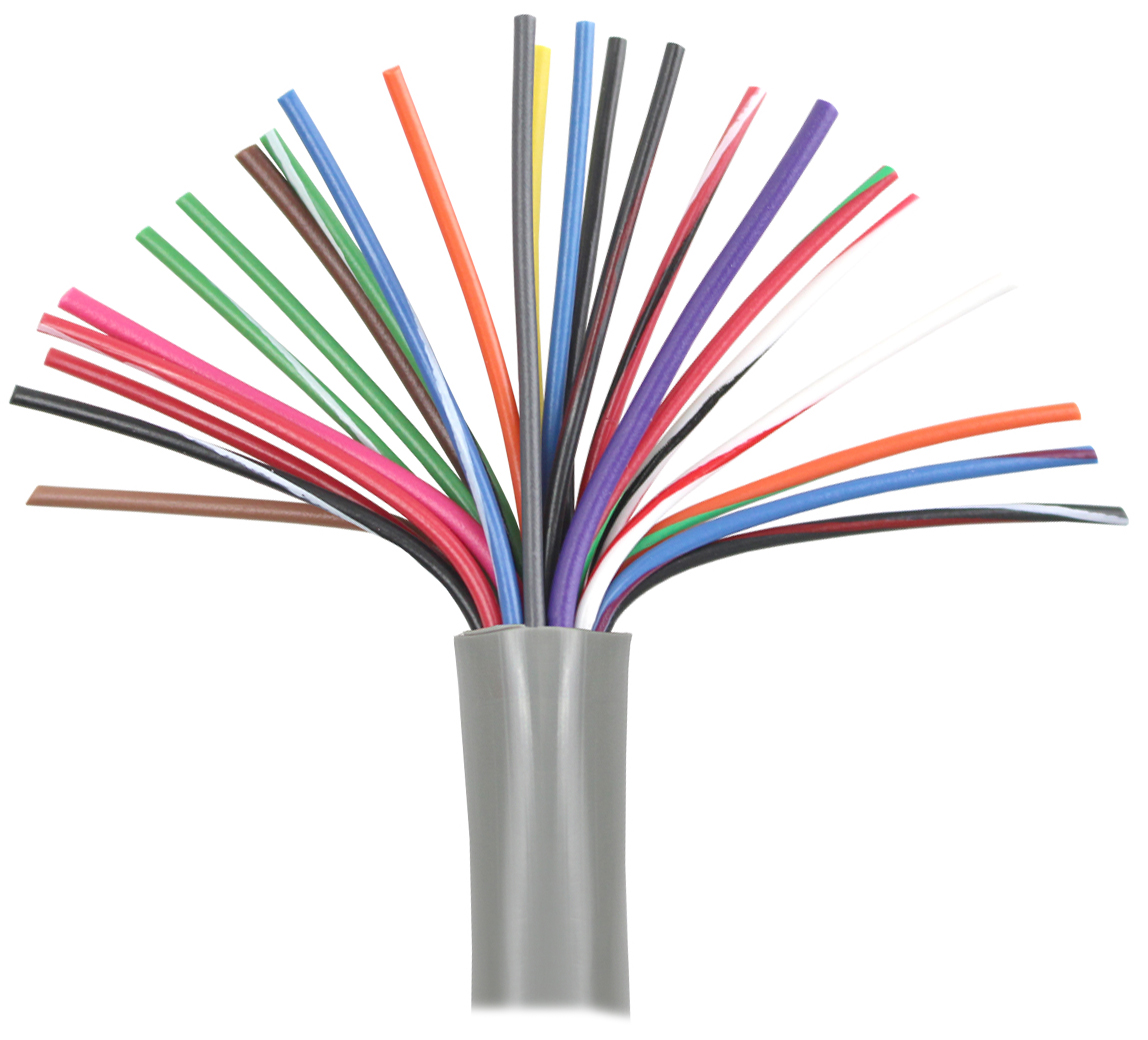

Multi conductor cable comes in two varieties, shielded and unshielded, but more on those in a bit. Multi conductor cable is most often used for control purposes. You will commonly find them in things like broadcast applications and communications equipment. Although they come in a range of sizes, you will find the most prevalent to be 22 gauge to 12 or 14 gauge. One of the best parts about multi conductor cable is the fact that there is the possibility for a great number of conductors. What I mean by that is you can get the same cable with only two conductors or as many as twenty-five. Not all cables have all the options but as you get smaller, you have the option for more and more conductors. This makes this type of cable extremely versatile as it can serve a wider range of applications.

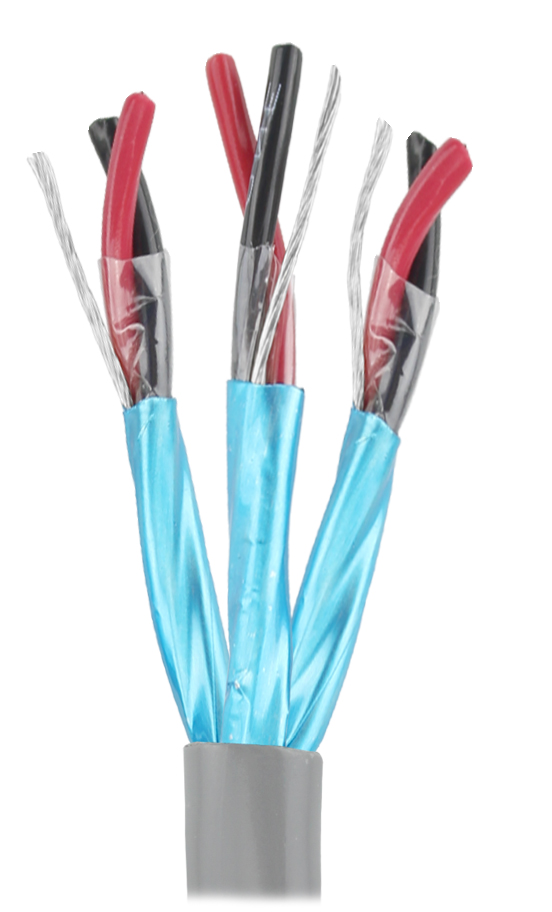

Shielded

When looking at shielded multi conductor cable the first thing that stands out is, the shield. Pretty obvious right? The shield itself is made from 100% Flexfoil aluminum with polyester foil facing outward. So why would you ever need to use shielded cable? The problem arises from environments that deal with electromagnetic interference. This type of interference can disrupt signals and prevent equipment from functioning properly. In some cases it can even damage equipment. Often times, factories and other industrial locations are full of EMF. So, by using shielded multi conductor cable you reduce or even eliminate the risk of EMF. This is why you’ll find this type of cable in industrial process control equipment. You’ll also find it in advanced signal transmission equipment in controlled environments. The durability and range of uses make this type of cable an ideal choice for industrial locations.

Unshielded

Unshielded multi conductor cable is pretty much the same as what was mentioned above, with a twist. This cable doesn’t have a shield. Can you believe that? This type of cable is useful in situations where electromagnetic interference is not a concern. In situations where you need multiple conductors in a durable cable that can handle a harsh environment. This is the place where unshielded multi conductor cable is ideal. With the varieties in gauge size and the number of available conductors, it’s clear why this is perfect for industrial applications.

"Solar wire is designed specifically to handle harsh outdoor conditions."

Solar Wire

Photovoltaic systems harness the sun’s energy for use as a power supply. In order for the system to function properly, it needs to have the correct wires. Solar wire is designed specifically to handle harsh outdoor conditions. It is resistant to sunlight, UV radiation, inclement weather and other elemental concerns. This type of wire is also surprisingly flexible. In this way, it is easier to install. When selecting solar wire, make sure it is rated for direct burial usage even if you don’t plan to bury it. This designation indicates that the wire is sturdier and more resilient to outdoor conditions. After all, you want your wire to last as long as it possibly can. Right?

Zip Cord

Zip cord is ideal for situations where you will need to use wires that have multiple conductors. Conductors which are color coded and parallel bonded. What that means is that the wires are attached side by side with different color insulation. This way you can get the various colors you need to complete a project. This makes distinguishing each wire at each point of connection easier. You can even get three and four conductors side by side if needed. This wire is an economical alternative to jacketed cable. Often, it is used with low voltage lights and trailer lights where multiple conductors need to be routed quickly and easily. Another common usage is DC circuits.

Shore Power Cord

When operating larger boats, you will most likely run generators while out on the water. When you dock your vessel, many places offer shore power. How do you connect to shore power? With shore power cord. This extremely durable cable is designed to transfer power from the shore to your vessel. This saves you from having to rely on generator power only. In order to be able to do this, the cable needs to be tough and resistant to damage. These cables are ideal in conditions where the highest degree of oil resistance is necessary. They are resistant to oil, acids, alkali, and ozone among other elemental conditions. You’ll usually find these on larger vessels.

Coaxial Cable (Coax)

Coaxial cable has an inner conductor that is encased by an insulator which is then surrounded by a conducting shield. It seems a little confusing, but trust me, it’s not. The inner conductor is used to transmit the signal and can be either solid or stranded. The outer shield serves to both trap inner EMF and prevent interference from external EMF. If you have cable television, you probably recognize this type from the cable tv box you use. Most commonly, coax cable is used as a transmission line for radio frequency signals. It can also be used for connecting antennas, computer network connections, digital audio signals and more.

Multi-Pair Tray Cable

In hazardous locations, cables could get easily damaged. To prevent this, the cables are often run along the ceiling in specialized trays. Each type of these cables varies more greatly than the previous styles we have discussed. That is because they are each designed for a particular purpose. So, you can get two pairs of conductors or three. Maybe you need a cable with an overall shield or individually shielded with no overall shield. It is situations like this that would call for multi-pair tray cables. These types of cable are often used for industrial control systems, power limited circuits, and even control circuits.

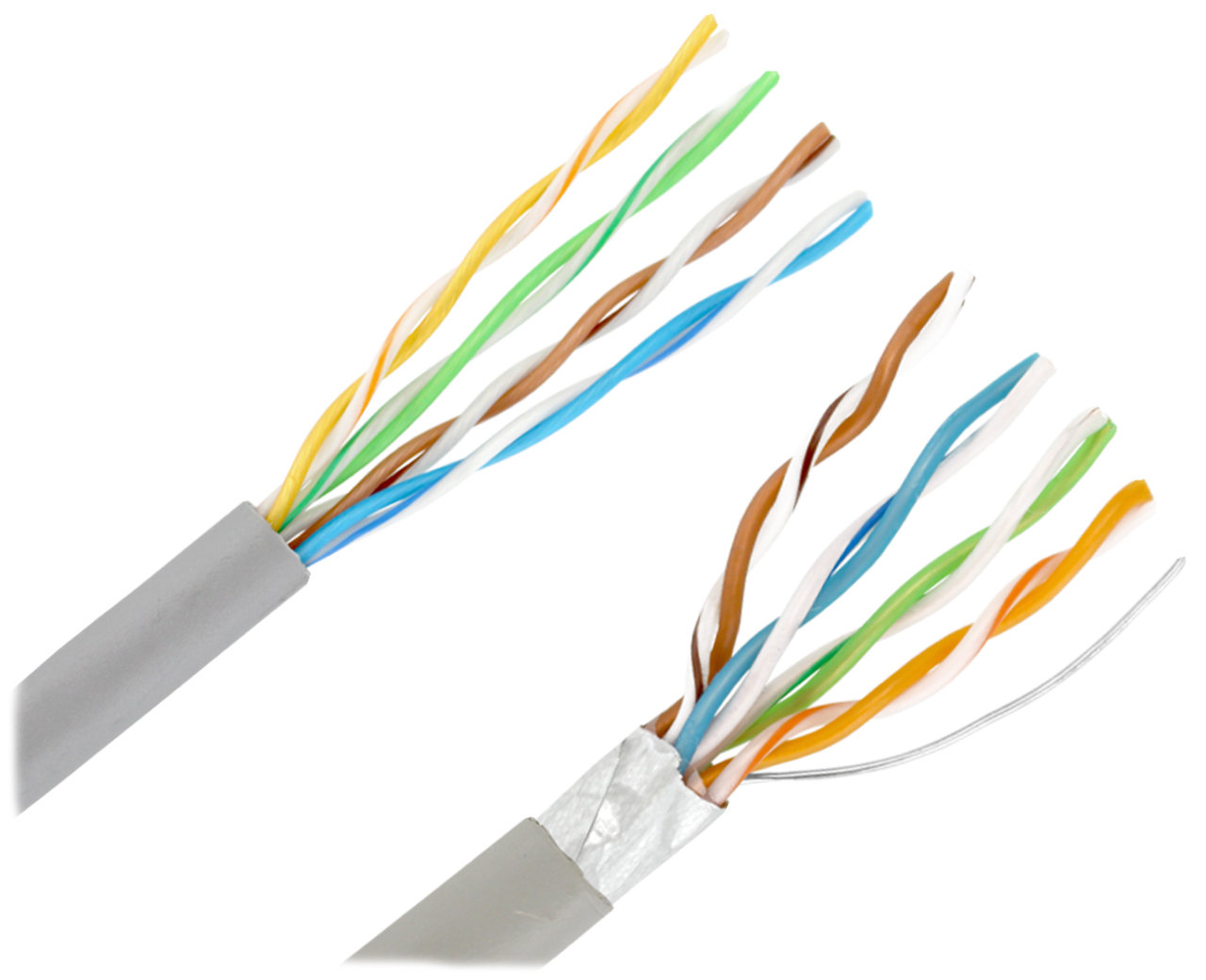

"Cat 5 cable is the industry standard in network connections."

Cat 5, 5E, 6 Cable

Cat cable is most often used in computer networks. It is a twisted pair cable designed for carrying signals. You’ve probably seen these running from your modem to your computer. Nearly all of these cables are unshielded. So, what’s the difference between them? Basically, it works like this. Cat 5 cable is the slowest of the bunch but still performs well. As the industry made improvements, they created 5E which is faster with less interference. As time progressed, Cat 6 was developed to be even faster. Many professionals have not implemented Cat 6 as of yet. This is for a variety of reasons but mainly because Cat 5E still performs extremely well. When installing, knowing your network speed will make selecting the correct cable much easier.

Importance of selecting the correct type

Now you have a better idea of the different types of wire and cable. You can see why it’s important to make sure that you are using the correct type for the job. Each type of wire or cable is designed for a specific purpose. Using the wrong types could lead to disastrous results. You couldn’t use wire where a cable is necessary as it just couldn’t carry the load. Similarly, you wouldn’t want someone using unshielded multi conductor cable where Cat cable was required. The bottom line is that each type of wire and cable serves its purpose well. With that in mind, we should always pay careful attention to select the correct wire or cable for the task at hand.