Selecting the Correct Cable Ties for your Applications

Posted by Pacer on 27th Nov 2024

What are Cable ties and how do they function?

Cable ties, as known as zip ties, hose ties, wire ties, or security straps, are a type of wire management material that is often used to secure and mount electrical wires and cables as well as hoses, and tubes. Invented in 1958, these useful tools gained rapid popularity and have now become ubiquitous with a wide range of industries and applications. You can easily find cable ties in everything from the automotive industry to retail usage and even in private home use.

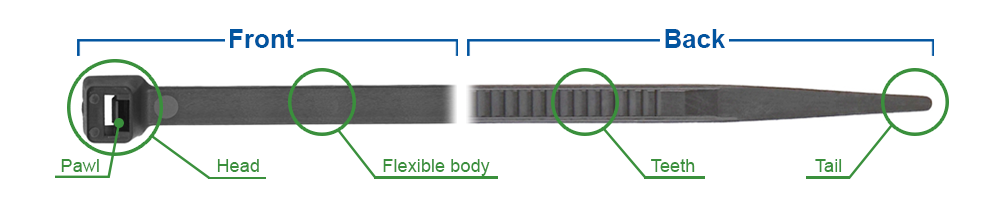

Cable ties work by wrapping around an object to be secured and locking into itself. This is achieved by passing the flexible tail of the tie through the head. Once the tail of the cable tie has passed through the head, the pawl in the head engages with the teeth on the tail to form a ratchet. It is this ratcheting motion that ensures as you pull the tail the cable tie will tighten. Cable ties are designed, for the most part, for single use and are not usually built for repeated use.

"It is the ratcheting motion that ensures as you pull the tail the cable tie will tighten."

What is tensile strength and why is it important?

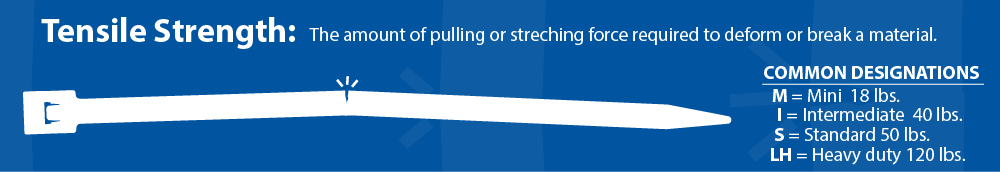

Tensile strength is a measure of the pulling or stretching force required to break or deform a specific material. It is a key measure to evaluate a material’s durability and the maximum load the material can handle. Basically, tensile strength is a stress test that determines a materials breaking point. This is critical when dealing with cable ties as different ties are designed to handle different loads, and as such, have different tensile strength. Knowing what tensile strength is makes selecting the correct type of cable tie a much simpler task.

The image below shows how cable ties are broken into groups based not only on their size, by more importantly, by their tensile strength. There are four main categories for cable tie tensile strength. The “M” designation is for “mini” and refers to a cable tie with a tensile strength of 18 lbs. “I” is the designation for “Intermediate” and indicates that a cable tie can handle a load of up to 40 lbs. The “S” is for “standard” used to designate cable ties with a tensile strength of 50 lbs. Finally, there is “LH” which is used to indicate “heavy duty” and can handle loads up to 120 lbs. With a firm understanding of tensile strength, let’s take a look at the various types of cable ties and their functions.

What types of cable ties are available?

Pacer offers cable ties in range of styles and tensile strengths. The four main types of cable ties we offer are: standard cable ties, Barb-ty, cable ties with mounting rings, and stainless-steel cable ties. Let’s look at the differences between these types and where you might use them.

Standard -

These are the type most people think of when they hear the term cable tie. They range in tensile strength from “M” all the way to “LH” and range in length from 3.9” to 30.5”. This means there is a standard cable tie for most applications. They are most commonly a natural or white color but are also available in black. We discuss the difference between the colors further down.

Barb-Ty -

Barb-Ty cable ties are a step up from the standard variety. Rather than the standard nylon pawl, Barb-Ty contains a metal further securing the bundle and offering a higher degree of protection and reliability. They are available in lengths ranging from 4.0” to 30.7”. Just like standard ties, Barb-Ty is available with tensile strengths ranging from “M” to “LH”.

Mounting Ring -

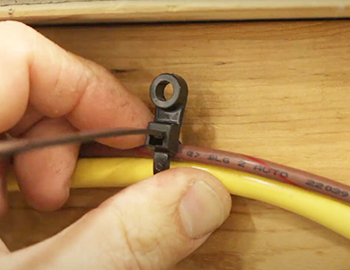

This type of cable tie is notable for its circular opening on top of the head of the tie. This ring is designed to allow mounting of the tie using a screw ranging from size #4 to #10. Mounting ring cable ties are available in both standard and Barb-Ty varieties. Pacer offers this type of cable tie in lengths ranging from 4.3” to 15.1” and with tensile strengths ranging from “M” to “LH”.

Stainless Steel -

If you need the strongest cable ties available, then stainless steel is the way to go. Made from 316 stainless steel, these ties offer the highest level of durability and protection possible. Pacer offers this type of cable tie in lengths ranging from 5.0” to 20.5”. Stainless steel cable ties are so potent that they exceed the “LH” designation instead having tensile strength ranging from 200 to 450 lbs.

What benefits do cable ties offer?

Cable ties offer a range of benefits not available with other types of wire management materials. This includes things like ease of use, versatility in applications, long-term durability, audible and tactile lock confirmation, color-coding, and the list goes on. The point is that cable ties are ubiquitous for a reason. They perform an essential duty easily and with almost no training. They handle tough environments and secure wire, and cable runs that would otherwise be difficult to work with.

![]()

![]()

![]()

![]()

![]()

What is the difference between Natural and Black cable ties?

Now that we’ve covered tensile strength, types of cable ties, and their uses, let’s review the differences between natural cable ties and black cable ties. The easiest distinction is that natural or white are for indoor use while black is for indoor or outdoor use, but it goes a bit further than that. Black cable ties are built from specialized materials that add ultraviolet resistance. This means that they can handle long-term direct sun exposure. Other ties cannot offer the same protection which is why manufacturers recommend only using UV resistant black cable ties for outdoor applications.

How do I choose the correct cable ties for my application?

The first thing to consider when selecting the correct cable tie for your application is what function will the tie perform. Are you securing wire or hoses? Are you mounting a wire run to the underside of a table? Are you using them to coil wire for storage or shipping? These questions help to determine which type to use.

For example if you are in fact mounting a run to the underside of a table, you would need to use mounting ring cable ties as they are the only one designed for mounting to other surfaces. Once you know the function the ties will perform and have selected a style, the next thing is to determine is the amount of tensile strength your ties will need to have.

For example if you are in fact mounting a run to the underside of a table, you would need to use mounting ring cable ties as they are the only one designed for mounting to other surfaces. Once you know the function the ties will perform and have selected a style, the next thing is to determine is the amount of tensile strength your ties will need to have.

If you are securing wire runs that weigh a lot, you would want to avoid using ties with a tensile strength rating of “m”. Otherwise, they will not be able to withstand the strain. Finally, with the type and tensile strength selected, you would need to decide on whether to use natural, or black. To recap, select the style based on the function, select the strength level required, then select the appropriate color. With these three steps, you should be able to accurately select the correct type of cable tie for your application.

Will I need specialized tools?

The truth is that most cable ties can be used without proper tools. Certain types, such as mounting rings and stainless-steel cable ties require specific tools to be installed properly. Just because you can install most cable ties without proper tools doesn’t mean that you shouldn’t use them. Think about this, as you pull a cable tie tight, what do you do with the tail? Sure you can cut it but now you’ve created a jagged edge that can damage surrounding materials especially in environments that deal with heavy vibration, such as on a marine vessel. Let’s look at three cable tie tools and where you should expect to use them.

Cable tie cutter -

As stated above, once a tie is installed, you’re left with the long tail. This is where the cable tie cutter comes in. This tool is specifically designed to handle most cable tie types and handle body widths ranging from 0.070” to 0.225”. It also has an easy-to-use adjustment knob so you can be sure you’re using the right amount of tension. This tool cleanly and quickly removes the end of the tail leaving a professional appearance.

Stainless steel cable tie tension/cutting tool -

This tool is a side entry cable tie tool for immediate positioning of the cable tie. This high-quality tool offers one-hand operation, is lightweight, and easy to use. The stainless-steel installation tools tension is controlled by the operator and even offers twist action cut-off. This tool is rugged, lightweight, simple-to-operate, and provides mechanical advantages over other standard installation tools.

Stainless steel cable tie tension tool -

The stainless-steel cable tie tension tool is designed for tensioning and coiling stainless steel cable ties. It is built for use with Type MLT (Pacer CMLT), Standard, Light-heavy, and Heavy cable ties. It is easy to use and built to handle the toughest marine conditions. Make sure to coil the tie end that remains after tensioning for a safe end. One thing that makes this tool exceptional is the fact that it installs parallel to the bundle.

What types of accessories and mounts are available?

Cable ties are designed to work with specialized accessories and mounts to enhance their abilities and increase the range of tasks they can perform. Although there are a variety of accessories, the main three that offer the most benefit are adhesive backed mounts, screw down mounts, and multiple tie mounting plates.

Adhesive backed mounts -

This type of cable tie accessory is used in applications where cable ties need to be secured to a surface. The adhesive used offers superior longevity and reliability. Each mount has four-way entry and is available in a range of sizes to match the cable tie size and the load required. These mounts are fast to install and simple to use. Adhesive backed mounts are available in either natural or UV resistant black.

Screw down mounts -

Screw down mounts are a simple way to mount cable ties if you do not having mounting ring ties. They allow for quick installation with a simple screw placed through the hole in the center. They work with screws ranging from #6 up to ¼” depending on the size of the mount you select. Each mount offers a low profile, excellent stability, and long-term rigidity. As with most of our cable tie products, they are available in natural or UV resistant black.

Multiple tie mounting plate -

When attempting to uniformly run wire or cable bundles, multiple tie mounting plates are the ideal option. They work by securing separate bundles in the same location. In this way, you can quickly organize wire and cable runs. All Pacer mounting plates work with #10 screws. Available in 3 or 6 mount options, multiple tie mounting plates offer ease of installation, long-term reliability, and a professional appearance.

Can I use any cable ties or accessories regardless of the manufacturer?

The biggest identifier of the quality of a product is the manufacturer. We strongly recommend against using just any cable ties. Like any other product, you want to be able to rely on it to perform the intended task. Always purchase cable ties from a manufacturer of distributor that offers high quality. When you purchase from Pacer, you can rest assured that we have put each product type through a battery of tests. We only offer exceptional products that meet or exceed industry standards. Many of our team members are boaters themselves, if we won’t put a product in our personal boats, we won’t sell it to you. Buy with confidence from a trusted supplier with over forty years in the marine industry.