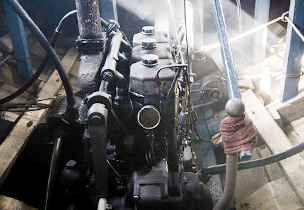

Simple Ways to Protect your boat, Check the Engine before Boating

Posted by Pacer on 26th Feb 2019

A boat engine is no simple piece of machinery. It is a complex connection of interlinking systems all working together in harmony. If anyone of those systems is not functioning properly, it can adversely affect all the other systems. Regardless of how much you know about boating and boat engines, you should take the time to learn what to look for to notice trouble before it becomes a serious issue. Knowledge, awareness, and preventative maintenance can go a long way to extend the life of your boat. Boat engines require very specific maintenance, preferably on a schedule. Adhering to this schedule will help extend the life of your boat and it's motor. Think of it like your car. You know that around every three thousand or so miles you’ll need to change the oil on your automobile. A boat is similar in principle. There are certain things that need to be checked at certain intervals in order to maintain a functioning system. Once you know what to look for, finding problems becomes a much simpler task. You should know how to check your hoses and pumps for signs of leakage. Be sure to look at your bilge as well for leaks. Check your oil and coolant to make sure there is enough, and that they look correct. For example, overly dark or sludgy oil would indicate its time for a change. This is also a great time to inspect your wires for corrosion or signs of melted insulation. Take a few minutes to inspect terminals and connection points for signs of damage or corrosion as well. Not all maintenance should be performed on a trailer or in a shop. Some maintenance can be done while actually on the water. It's best to test a system under pressure to ensure everything is working fine. That way will ensure that your boat will hold up under stressful conditions. It is important to note that this should be after you have checked everything thoroughly while on land and are certain crucial systems are maintained properly. Once you get on the water, be sure to check your oil pressure and volt/amp meters just to make sure everything is good to go. These are just a couple of ideas on what you should be checking. The problem is, there is no one size fits all maintenance list for boats. It really depends on the size, make and model of your boat as to what you’ll need to pay attention to, but the basics will always be the same. Using the list below will get you started, but make sure to educate yourself on your particular boat needs.

Things to Check:

- Hoses/Pumps for signs of leakage or cracking

- Bilge and bilge area for signs of leaking or damage

- Oil level and quality

- Coolant levels (if applicable)

- Wires for corrosion or damaged insulation

- Steering connections

- Electrical terminals and connection points

- Switches and switch covers

- Batteries and battery switches

- Your toolbox. That's right. Make sure you have a toolbox with more than what you'll need.

A multi-meter can help identify problems:

Navigating an electrical system can be a daunting task. Knowing what voltage and amperage the wires and cables are carrying is impossible without the proper tools. This is why having a multi-meter is essential in isolating issues. This tool can allow you to tell how much voltage or amperage a cable is carrying without having to even touch the cable yourself. Knowing this information can help you to quickly identify where a problem area is located. Perhaps a cables termination or splice has become corroded but you cannot see it due to the sealant, tape, or heat shrink that covers it. A multi-meter will allow you to find the trouble spot much faster than manually testing each wire. Looking for a different tester? Find it here.

New lugs can create more solid connections:

People usually consider things like batteries, switches, panels and the like but tend to overlook terminals and connections. These can become corroded or damaged over time and if ignored, will become much bigger problems. An easy one to maintain is your battery lugs. They create a strong connection and are designed to withstand the harsh marine environment. These lugs have no exposed seams and are tin-plated to ensure conductivity and longevity. Many lugs are only meant to make an electrical connection, but not these. Having lugs that are designed for protecting the end of a cable and creating a strong, durable connection is the best way to ensure the life of your electrical connection.