The Proper Way to Use Fork Terminals

Posted by Pacer on 1st Dec 2021

We are going to look at how to properly install fork terminals in a real-world application, but first, let us touch on what fork terminals actually are and what types are available.

What are fork terminals and what separates them from other types of terminals?

Fork terminals are one of many types of crimp connectors that are used to join a wire to another point in an electrical system such as a bus bar or a stud. The thing is forks are different than other types of electrical wire connectors in that they are designed to accommodate change. Let me explain. When you use wire connectors like a ring terminal, that ring must slide over a stud or be secured with a screw and then be locked into place. This creates a somewhat permanent connection. In order to change the ring, you would first need to loosen and remove the binding screw then remove any other connectors in the way. With forks, their open-end allows them to be removed much easier. By simply loosening the binding screw, you can quickly remove a fork terminal. Then you can make any changes you need and reapply it without having to totally remove the binding screw or any other electrical connector types that may be in the way.

What types of forks can I use?

Fork terminals come in two main varieties: locking forks and flanged forks. Although very similar, these two styles are significantly different. Locking forks are shaped in such a way that they snap onto and hug the stud. This means that it requires a little force to install them but also ensures that they will not fall off on their own. Flanged forks on the other hand have the tips of the fork tines bent upward. This allows the fork terminal to grip the mount or screw that it has been attached to. Not only does this reduce the risk of the terminal coming loose, but it creates a stronger connection as well. These crimp connectors are some of the strongest electrical connectors you will find. Okay, since we have that out of the way, let us take a look at which types of insulation are available for fork terminals.

Flanged Fork

Flanged Fork

Locking Fork

Locking Fork

What types of insulation are available and where would I use them?

When selecting the right fork terminal for your application, one important considerations is the insulation on the terminal. Pacer offers marine grade fork terminals in heat shrink, nylon, vinyl, and non-insulated. Heat shrink fork terminals have an inner lining of epoxy which activates when heated. This epoxy melts and creates a superior environmentally sealed connection point. Heat shrink fork terminals also offer relieve bending stresses. Nylon fork terminals are the next best option. They offer a solid level of protection and make crimp inspection easy with the translucent insulation they carry. Vinyl fork terminals offer a decent level of protection and are simple to install. They are a common choice when higher levels of protection are not required. The last insulation option is non-insulated. This is the most economical choice and is a solid choice for use inside secure areas. Pay careful attention when selecting the insulation for your fork terminals. It really depends of how much protection you are looking for.

Heat Shrink

Nylon

Vinyl

Non-Insulated

How to properly install Fork terminals

In order to properly install fork terminals, you will first need to gather the proper tools and parts. For this example, we will be using 14-gauge wire, heat shrink locking fork terminals, a bus bar, a wire cutting/stripping tool, a wire crimping tool, and a heat tool. With all of our equipment and tools ready, we will start by preparing the wires using the stripping/cutting tool.

Step 1

Each wire should be stripped to the correct length based on

the fork terminal you are using. Remember that the bare conductor should be

fully inserted into the barrel of the fork terminal while the insulation is

butted up to the body of the fork terminal. Take a look at the image to the

right to see an example of properly stripped wires.

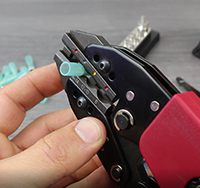

Step 2

Once the wires are prepared, insert them into the body of

the fork terminal paying careful attention to the conductor and insulation

length. With the wire in place use the proper crimp tool and complete one full

ratchet cycle. Inspect the crimp to make sure that it is in the correct

location and that the fork terminal was not damaged from improper tool usage. Repeat

this action across all wires that will be attached to the bus bar.

Step 3

With all of the wires properly crimped, it is time to

perform the tug test. This will ensure that the fork terminal has been seated

properly and the crimp is solid. To perform a tug test, you will pinch the wire

and terminal in separate hands and gently tug apart applying sufficient force

to test the strength of the connection. You should feel zero movement or give

indicating that the connection is in fact strong.

Step 4

Now it is time to activate the epoxy-lined heat shrink in

order to fully enclose and protect the connection point. To ensure that the

heat shrink is properly activated, use the correct heat tool and keep the heat

tool far enough away as to not burn the insulation. Completed wires should be

set to the side until the next step.

Step 5

With every wire now prepped, you are ready to start adding

them to the bus bar. Orient the wires in the correct positions for your

application. After each fork terminal is added to the bus bar, be sure to fully

tighten the binding screw. With all wires in place, double-check each screw one

last time. That’s it. You have properly installed your fork terminals.

Here are all the steps in a short video to make the process easier. There you have it. You have not only created a solid electrical connection with each fork terminal you installed, but you have also made it so that future maintenance and adjustments will be simple to manage. In this way, fork terminals offer advantages that you just cannot get with other types of terminals. The next time you are maintaining or adjusting your electrical system, consider fork terminals for the versatility that they offer. Before we wrap this up, let us briefly touch on what we consider to be some important considerations.

Important considerations

To make sure that you are creating the most secure, longest-lasting connections possible, there are a few things to consider. While these may seem obvious to some, these are things that can easily be overlooked if you are not careful.

Wire Type

Not all wire is the same. You have UL (Underwriters Laboratory), SAE (Society of Automotive Engineers), as well as other types. Each type of wire is designed with specific applications in mind. To learn more about various types of wire, click here.

Wire Size

Another important thing to consider is the wire size in relation to the application and your fork terminals. The last thing you want to deal with is to have 14-gauge wire when you need 12 gauge. Just like the type of wire, having the correct size is essential.

Insulation Type

Not all fork terminals are the same and this is especially true when it comes to the insulation on the terminal. You can choose from bare, nylon, vinyl, or even heat shrink insulation. Each type is built with specific applications in mind. For a detailed breakdown of the different insulation types, click here.

Additional Protection

Some applications will require a higher degree of protection depending on the environment that they are in. Sometimes you may just want to increase operator safety. It is in situations like this that you will want to consider adding protection such as a bus bar cover. These covers can protect connections and prevent accidental operator contact. To learn more about covers, click here.

Now you know how to not only properly prepare, inspect, and install fork terminals, but you also know about some important factors to consider. We hope that this article helps you to get more out of your electrical connections.