Top Reasons Boats Fail, Belt Wear or Breakage

Posted by Pacer on 25th Feb 2019

When your belt breaks you may not immediately notice. You may notice a squeaking sound or other unusual noise coming from the pulleys. Never ignore an unusual sound on your boat. It can lead to long term, and even permanent issues or damage. Once a belt is out of commission, your water pump and alternator will soon stop working. So even though you may not have heard a noise, you’ll notice that either your overheat light comes on or that your voltmeter shows that your alternator isn’t charging. These are extremely problematic signs that either way, must be addressed immediately. If you don’t have a spare belt with you, then head back to shore as carefully as possible. If you are absolutely stuck and in danger, in some cases, you can rig up a temporary belt using everyday materials such as thick fishing line or certain fabrics but it’s much easier to just be prepared. Often times, creating a temporary belt doesn't work well, if at all, so don't count on it as a solution. The bottom line is to be prepared. Carry an extra belt and the tools needed to change it out. Once you have your boat in a location where you can safely assess the problem and implement repairs, start by inspecting your pulleys. When a belt fails on a boat, often times it is due to rust. Each pulley should be rust free and as smooth as possible. This ensures the motor runs at optimal capacity. One small clump of rust will wear on your belt thousands of times per minute. With the belt removed, run your fingers over each and every pulley, feeling for rough spots. Remove any rough spots by wet sanding the area with care. Once done, it is a smart move to protect the pulley with a fresh coat of paint or protectant. Once your pulleys are ready, put your new belt in place and make sure it is secure.

Prevention

Make sure to inspect your belt before going out on the water. Tighten if needed. Look for corrosion on the pulleys and make sure to remove any corrosion before replacing the belt. When your belt is off, inspect each pulleys bearings. You can do this by turning all of your pulleys by hand and feeling for unusual resistance or drag. This can be a sign of damaged or worn bearings. Play it safe and replace anything that you think could become a potential issue. Make sure to apply this same test to your alternator, especially if your alternator has been rebuilt at any point. These steps can help prevent a belt related issue out on the water.

Tools you'll need:

- A spare belt

- A basic marine toolkit

A Temperature Meter can alert you to trouble:

One of the first signs that there is an issue with your belt is your temperature gauge. When the belt is not connecting the pulleys, your system will not be cycling cooling water through the block and head. This will cause the temperature to rise very quickly. As the temperature rises, moving parts will begin to expand and make contact with other moving parts. Run it too long and you may end up seizing your motor. The easiest way to prevent this is to have a durable temperature meter installed where it is easy to monitor. Using a temperature meter will allow you to take note of overheating before it becomes an issue. If you use a digital meter, make sure that the temperature meter you use has a day time readable screen.

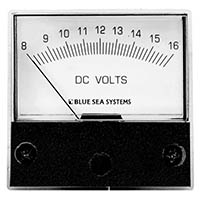

Utilizing a voltmeter alerts you to potential issues:

Another indicator that your belt has broken is your voltmeter. Without a belt running in your system, your alternator is not charging the battery. This can lead to several issues but can easily be prevented by utilizing a voltmeter. A voltmeter will indicate whether the alternator is charging or not, alerting you to an issue with either the belt or the alternator itself. This is why preventative maintenance is essential in a marine vessel. On land, you can walk to safety. On the sea, it's a different story. By installing and paying attention to your voltmeter, you can be aware of an issue as it arises, rather than once trouble sets in. As stated above, if you're using a digital meter, make sure that it has a day time readable screen.