Categories

- Wire & Cable

- Multi-conductor & Signal Cable

- Battery Cable Assemblies

- Terminals and Connectors

- Electrical Parts

- Electrical Tools

- ID Products

- Wire Management

- Tape & Sealant

- Mounting Panels & Panel Blanks

Need Help?

Click HereGet a Business Account

Apply HereMarine Battery Cable

![]()

![]()

![]()

![]()

![]()

![]()

![]()

What is marine battery cable?

Marine battery cable is a durable, high-quality cable designed to handle the harshest marine conditions. To survive in a marine environment, battery cable needs to be able to withstand the constant vibration that a boat is subject to, as well as survive a wide range of other environmental conditions. Additionally, an essential quality that this type of cable needs to possess is flexibility.

In a boat, wires will often need to run through tight spaces and make frequent bends and turns. A standard cable may not be able to handle the turns and bends without compromising the integrity of the cable itself. It is for reasons such as this that Pacer developed a unique line of marine battery cable that carries a proprietary insulating jacket. This cable is designed for durability, flexibility, and longevity. We make our cable so durable, that it is designed to out-live the battery itself.

"We make our cable so durable that it is designed to outlive the battery itself."

How to select the right battery cable for your project?

Selecting the right battery cable is easy when you know what you’re looking for. The first thing to consider is the type of battery cable. The two most common styles are UL and SAE. UL is rated for 600V, has a thicker insulation, and more conductors. SAE, on the other hand, is rated for 60V, carries a thinner insulation, and offers less conductive material. This makes UL slightly heavier than SAE. Once you have the style chosen, the next step is selecting the correct gauge. Battery cable typically goes from 6 gauge to 4/0 aught.

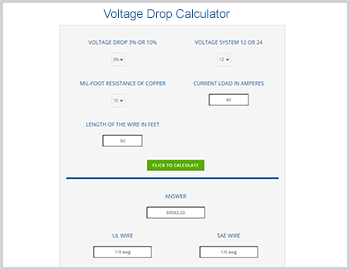

The size will be determined by the power requirements as well as the length of the cable run. Use our convenient voltage drop calculator to help you determine the correct gauge and length of battery cable. The last consideration is color.

The color of the insulation can be used to determine the purpose of the cable. Now you know the factors you need to consider when selecting a battery cable for your application. If you are using battery cable to create full assemblies, be sure to use high-quality lugs and epoxy-lined heat shrink to get a superior, environmentally sealed connection.

What makes Pacer cable superior to the competition?

With a focus on things like flexibility and longevity, Pacer worked out how to make high-quality marine battery cable. Fast forward 40 years, and add the idea of continual refinement, and you have the process that created the superior marine battery cable that the competition struggles to compete with.

With nearly four decades of refining, testing, and further refining the processes and methods, Pacer has created a marine cable that is unparalleled in the marine industries. Take a look at just a few of the more obvious reasons Pacer marine battery cable surpasses any test thrown its way.

Where is marine battery cable implemented?

Pacer marine battery cable is implemented in some of the biggest boats on the water. They are also used in everyday boats around the world. Our battery cable is commonly used to replace existing older cables when not going into new boats. As boats age, so do the wires and cables that power them.

Oftentimes, when a boater finds that they have faded battery cables, cracked battery cables, or damaged battery cables, they turn to us for replacements. If you are looking to make your own assemblies, you will need the proper tools, battery posts, lugs, and heat shrink. Lucky you came to the right place. Once you know what you need to get, make sure you pay careful attention to the insulation color.

How do I know which color of insulation to choose?

In order to choose the right color cable, you should have a basic idea of what the colors represent. The whole concept of coloring the insulation is to make its intended usage obvious for anyone working with the cable. This, in turn, makes the process of maintaining, repairing, and replacing wires and parts easier as you can visually identify the wire.

For example, let's say you want to replace the positive battery cable. Well, knowing that the cable is red is going to make this task much easier. That is the logic behind the color chart. Below you will find a basic chart that explains the color code for marine battery cable. Now you'll understand why having such a method in place is important.

| Color | Item | Application | Available Gauges |

|---|---|---|---|

| Black | Negative | Negative connection | 6AWG - 4/0AWG |

| Red | Battery Power | Power distribution from battery | 6AWG - 4/0AWG |

| Orange | Accessory Feed | Ammeter to alternator or generator Distribution panel to accessory switch |

6AWG |

| Yellow | Ground | Ground line | 6AWG - 4/0AWG |

| Green | General Usage | General Usage | 6AWG - 2AWG |

| White | General Usage | General Usage | 6AWG - 2AWG |

What gauge and length of cable do I need?

The gauge and length of cable required vary from job to job but will be based around the amount of power required. The problem is that people tend to forget about voltage drop. Voltage drop is where the electrical potential is decreased in an electrical circuit. This dissipation of energy occurs due to the resistance or impedance caused by the cable itself.

Unfortunately, it is an unavoidable fact of life. The good news is that we have you covered. We have a free handy voltage drop calculator that makes determining the proper gauge a simple task.

What is the manufacturing process like?

The manufacturing process starts by selecting the highest-quality materials possible. Class K copper is chosen for its resistance to corrosion and its high conductivity. This copper is annealed and finely stranded to offer unparalleled flexibility and resistance to vibration. The next step involves tinning the copper. The tinning process serves two functions. First, it creates an additional layer of protection that helps prevent corrosion from taking hold. Second, tinning increases conductivity.

These factors work together to make the cable more durable and more effective. The final step is adding proprietary insulation that was designed in-house and focuses on long-term usage and flexibility. All Pacer marine battery cable is manufactured in-house in Sarasota, FL, USA. Each step of the manufacturing process is designed and refined to make the highest-quality marine battery cable possible.

![]()

Copper ![]()

Tinned ![]()

Stranded

Why use tinned conductors?

When you are dealing with the marine environment, you are dealing with exposure to moisture that a cable wouldn’t normally need to deal with. The problem lies in corrosion. Bare copper in itself is resistant to corrosion, but that resistance is removed when the copper is subject to continual exposure to moisture. This is where the tinning process comes in.

By tinning the bare copper, we extend the life of the battery cable by heavily reducing the chances of corrosion occurring. To make it even better, if corrosion does somehow find its way to your cable, it will spread much slower. The bottom line is that if your cables are going to be used in a marine environment, they need to be tinned.

How is the insulation proprietary, and what makes it better?

When dealing with electrical wiring in just about any kind of boat, there can be a lot of bends and turns that the wire and cable will be subject to. You absolutely need to use a marine wire or battery cable that is built for just that task. The last thing you want is a cable with inferior insulation that will not bend easily or will crack under stress. We focused on developing insulation that can bend and curve in all directions and is even flexible enough so that it won't crack or split.

The installation will always go much easier when you use a marine battery cable that was designed to be installed in tight spaces with bends and turns. Not only is the insulation designed to be flexible and durable, but it is also made to be highly resistant to a host of environmental conditions.

![]()

Flexibility

![]()

Durability

What resistances does Pacer Marine Battery Cable offer?

In order for marine battery cable to survive in harsh conditions, it has to be built tough. Tough enough to handle conditions that it might not be subject to very often, if ever. Marine battery cable can easily be exposed to moisture, oil, acid, gasoline, abrasion, and more.

The point is to make it resilient enough so that, in the event it is exposed to a certain condition, it will have a solid chance at outlasting the environmental hazard. Below you will see a list of resistances that can occur in a marine electrical environment. Pacers proprietary insulation is designed to handle all these environmental hazards, making it superior to much of the competition.

![]()

Moisture ![]()

Acid ![]()

Abrasion ![]()

Alkali ![]()

Oil ![]()

Gasoline ![]()

Flame

What compliances does Pacer marine battery cable meet?

Pacer's marine battery cable meets and exceeds multiple compliances set in place by governing bodies. The point of compliances is to create a baseline of quality that manufacturers should live up to. Pacer has designed and refined its processes to the point that they actually exceed several of the compliances that have become industry standards. What does that mean?

It means that Pacer Marine battery cable surpasses the standards that have been set in place, making the cable superior when compared to many of the competition’s cables. Below you will find a list of the compliances that Pacer Marine battery cable meets or exceeds. Click on the link to be taken to the corresponding compliance.

What are some advantages of using our cable?

The advantages of using Pacer cable include its durability, flexibility, and longevity, as well as its high conductivity and resistance to corrosion. Additionally, we went over the resistances this cable offers and the compliances it meets.

With Pacer marine battery cable, you're getting the culmination of nearly forty years of experience and the highest quality marine cable available. Again, this cable is so tough, it is designed to outlive the battery itself.

Which industries use Pacer cable?

Pacer’s marine battery cable is so versatile that it is utilized by a wide range of industries. You can find it in the power management industry, automotive industry, RV industry, data management industry, marine industry, and multiple others. Take a look at the list below to see just some of the industries where you will find Pacer marine battery cable.

![]()

Marine

![]()

Automotive

![]()

RV's

![]()

Communication

![]()

Golf Cart

![]()

Audio

![]()

Solar

![]()

Batteries

![]()

Database

![]()

Equipment

*This page was updated on 1/30/2025*