Categories

- Wire & Cable

- Multi-conductor & Signal Cable

- Battery Cable Assemblies

- Terminals and Connectors

- Electrical Parts

- Electrical Tools

- ID Products

- Wire Management

- Tape & Sealant

- Mounting Panels & Panel Blanks

Need Help?

Click HereGet a Business Account

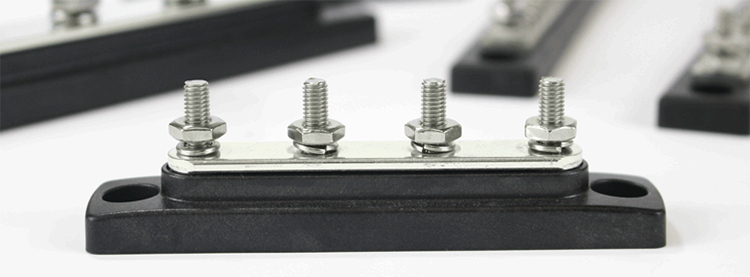

Apply HereBus Bars

What is a bus bar?

A bus bar is a metallic bar or strip that is used for local power distribution. That is to say that you can connect several wires to a single bus bar, and they will connect into one circuit. They are a useful way to consolidate wires into a single location. In fact, bus bars are often used to consolidate positive or negative wires. In some cases, such as our dual row bus bar, you can combine positive wires and negative wires in a single block. Commonly, bus bars are used as a proper ground for circuit protection.

"They are a useful way to consolidate wires into a single location. In fact, bus bars are often used to consolidate positive or negative wires."

Pacer Group's bus bars are tinned plated copper for higher conductivity. This makes them ideal for use in tough conditions where corrosion may be an issue. We carry a wide range of bus bars so that you can find the type that best suits your specific needs. Whether you are looking for a 100-amp mini bus bar, a 600-amp power bus bar, or even a sealed bus bar, we have them, and more. One question we often receive from customers in our retail store concerns the difference between a bus bar and a terminal block.

Where are bus bars implemented?

Bus bars are implemented across the marine industry

Bus bars are implemented in applications where power needs to be distributed from a central hub. They are a very common part found in the marine industry. All Pacer bus bars are perfect for new installs as well as when replacing or maintaining equipment on your boat. If you have corroded bus bars or damaged bus bars then these are the perfect parts for your needs. All you will need are the proper tools, the correct wire, and the correct terminals. Let us shift our focus to the difference between bus bars and terminal blocks.

What is the difference between a bus bar and a terminal block?

The main difference between a bus bar and a terminal block is that a bus bar gathers multiple wires together for electrical distribution whereas a terminal block has separate circuits where each incoming wire is paired with an outgoing wire. The simplest method to tell them apart is by the body. If the body is one solid piece of tinned copper, then the electricity will be distributed equally and as such, it is a bus bar. If the body is instead segmented into pieces of tinned copper that are separated by plastic ridges, then those are individual circuits, and as such, part of a terminal block.

![]()

![]()

What types of bus bars are available?

Bus bars come in a range of sizes to accommodate a variety of needs. The biggest difference between bus bars is the amperages that they can handle. Think about it, a bus bar that can handle 100 amps will not work where 250 amps are required. So, the most important question to ask yourself before choosing a bus bar is how many amps will my application require? Below we will take a look at the different types of bus bars we offer and what makes them advantageous.

Mini bus bars are the smallest size bus bar that we offer. They are for use in applications that require 100 amps of electrical current. These types of bus bars are ideal in situations where limited space is an issue, or the amperage demands are not very high.

Common bus bars are the next step up from mini bus bars in both size and amperage handling. Our common bus bars are rated for 150 amps of continuous power. They are called common as they are the industry standard size and as such, are the most common.

Maxi bus bars are for use in applications that require 250 amps of continuous power. They are another example of a bus bar that you will find in frequent use due to their amperage rating. Maxi bus bars are available in two distinct styles to meet various needs.

Power bus bars are the highest amperage bus bars that we offer. With the ability to handle 600 amps of continuous power, these are the big guns. They are even substantially larger than the other style of bus bars that we carry.

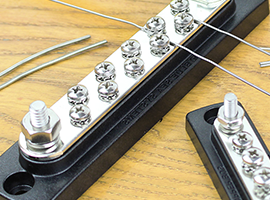

Dual row bus bars have two separate bus bars built into one. In this way, you are able to connect two circuits to the dual row bus bar. Most often, they are used to combine negative and positive buses on one block.

Sealed bus bars are designed to mate with Deutsch environmentally sealed connectors. They are sealed as the name implies meaning that they can handle the harshest conditions you can find in a marine environment. We offer these in two varieties.

Where would I use a bus bar?

You would use a bus bar in just about any application where you need to safely distribute power throughout an electrical system. I think of a bus bar as a hub where the power comes in on the posts and is then distributed to the wires connected to the screws. Rather than have ten wires running all over the place, you can consolidate them into a single unit, while grounding the circuit. It's a win-win situation. It is this consolidating function that makes these electrical parts ideal for use in marine environments.

What materials are bus bars made from?

In order to get the highest quality bus bar possible, we have to make sure that they are made with the highest quality materials. Most of the bus bars that we offer are made from Tin-plated copper CDA 110/UNS1000 as the conductive material. Additionally, they have reinforced polycarbonate as the base material. These two materials explain why these electrical parts are so durable and long-lasting. It’s important to note that some bus bars may have different materials in it's composition. Be sure to check the specific product of your choice. This way you can be sure you’re getting the exact part you want.

What advantages does a sealed bus bar offer?

Sealed bus bars offer a few distinct advantages over some of the other types such as a superior liquid tight connection point and a quick installation time. In order to handle the toughest marine conditions, sealed bus bars use the same “plug-and-play” mechanic behind environmentally sealed connectors. This means no more removing screws to add a ring terminal. It also means no more worrying about screws that loosen over time. Instead, it is just plug-it-in and go. Additionally, they install in about 1/10th of the time of a conventional bus bar. This makes them an ideal choice for use on production lines.

Can bus bars withstand tough marine conditions?

Yes, our bus bars can withstand the toughest marine conditions out there. As we said above, our bus bars as tinned copper, which is not only highly conductive but highly resistant to corrosion as well. We do not offer tinned copper bus bars by chance. It was a decision to offer a tougher, more reliable bus bar so that can know it is going to function when you need it to.

What are bus bar covers?

Bus bar covers are exactly what they sound like, covers, for bus bars. You may be thinking, why would I need one? Well, a cover does more than just protect the bus bar, the wire, and the terminals, they increase the safety as well. A bus bar has power running through it. Power that can shock and potentially injury or even cause death to yourself or someone you care about. Bus bar covers reduce the risk of accidental shock that would occur if a live bus bar was touched. Seriously, a cover could potentially save lives.

What are power posts?

Power posts are designed to connect high amperage cables in a secure method. They are often used on positive cables, to branch out to high-amperage devices. You can also use them on negative cables as a convenient ground post. Regardless of how you use them, power posts provide a secure connection for high-amperage cables. What kind of protection do they offer? Each power post comes with an insulator cap. This cap protects against accidental grounding. Each type of power post that we offer is built with a specific application in mind.

What types of power posts are available?

We offer power posts to handle a range of applications and needs regardless of the fact that you may need a mini power post or even a power post plus. The first step is understanding the difference between and where each one might excel. Below we will take a look at each of the types we offer and where you might want to use them.

Mini power post

Our mini power post is designed to be used with ring terminals and is not rated for amperage. Why not? Well, the amperage flow between terminals is stacked on the post and is heavily dependent on the terminals and wires used.

Power post

Standard power posts are for use with either 3/8" ring terminals or 5/16" ring terminals depending on the style you select. Again, just like the mini power posts, standard power posts are not rated for amperage. Remember, they are not rated as the amperage flow between terminals is stacked on the post.

Power post plus

Our power posts plus are the next step up from standard power posts and are ideal for applications where 150 amps of continuous power are required. They are available in either 3/8” posts or 5/16” posts. The main difference between the power post plus and other types is the fact that it works as a bus that can distribute power to smaller wires.

Dual power post

A dual power post carries two posts on one body. It is for applications that require a termination point for extending the length of outboard harnesses or other conductors. Each dual power post comes with a red boot and a black boot for added protection.

What are feed through connectors?

Large cables passed through holes are subject to chafing even if they are protected by grommets or other surfaces. Feed through connectors eliminate chafing and provide excellent strain relief for the cable. Rather than passing the cable through a hole in the wall or other surface, that hole is occupied by the feed through connector. This durable solution is designed for long term applications.

*This page was updated on 8/2/2022*