Categories

- Wire & Cable

- Multi-conductor & Signal Cable

- Battery Cable Assemblies

- Terminals and Connectors

- Electrical Parts

- Electrical Tools

- ID Products

- Wire Management

- Tape & Sealant

- Mounting Panels & Panel Blanks

Need Help?

Click HereGet a Business Account

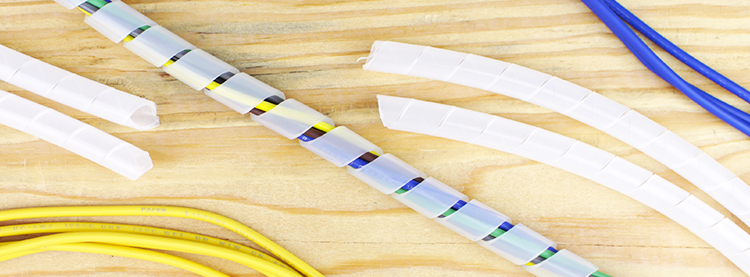

Apply HereSpiral Wrap

What is spiral wrap?

Spiral wrap is a type of wire management material that is used to protect wires and other materials from a range of hazards. It is known for its ease of installation, its high level of protection, and its long-term durability. Spiral wrap is one of the few wire management materials that can offer multiple functions depending on how you use it. It can hold objects in a way that offers more protection but less flexibility or vice versa. This is one of the reasons that spiral wrap is used in so many industries and applications. When selecting the correct diameter for your application, it is important to know just how to use spiral wrap.

"Spiral wrap is one of the few wire management materials that can offer multiple functions depending on how you use it."

Where are these products implemented?

Spiral wrap is a simple yet direct method for wire protection

Spiral wrap is implemented in applications that call for wires and cables to be protected from abrasion and other similar hazards. It is known in the marine industry due to its simplicity of use and longevity in harsh conditions. Spiral wrap is useful in new installations as well as when replacing parts. Say that you have unprotected wires or cables that may be subject to abrasion, then spiral wrap is a perfect solution. All you will need are the proper marine wire and battery cable. Now that we have covered where these products are implemented, let us look at how to you spiral wrap.

How do I use spiral wrap?

Being made for flexibility, spiral wrap is surprisingly easy to use. Once you have your wires and cables properly lined up and bundled, you just need to work the conduit around the bundle itself. To put it another way, you place the end of the spiral wrap against the bundle and then wrap it around the bundle in one continuous motion. Spiral wrap is also a great choice for protecting tubing. If you are looking for the highest level of protection possible, keep the edges of the wrap close together. If, on the other hand, you are looking for protection with flexibility, then just leave a larger gap between the edges. It goes on easy and offers lasts long-term making it an obvious choice. Speaking of protection, one question we often receive is about the benefits that spiral wrap offers

What benefits does it offer?

Spiral wrap offers a range of benefits including simplified installation, abrasion protection, extreme flexibility, and easy wire breakouts. One reason manufacturers chose spiral wrap is the fact that it can be used to professionally wrap a long wire bundle in a matter of minutes. This saves time while offering that high level of protection we mentioned earlier. Let’s talk about easy breakouts for a second. When you encase a wire run with split conduit or wrap it with electrical tape, you limit the ability to run wire branches from that main trunk. With spiral wrap, that’s not an issue. The gap between the wraps allows sufficient room to pull out single wires and run them in an alternative direction. Another benefit of spiral wrap is the fact that you can use spiral wrap in just about any location wires are found.

Where is spiral wrap used?

Many industries have specific demands which require specific solutions. Spiral wrap is one of the few wire management materials that can accommodate a range of these demands. You can find spiral wrap on manufacturing production lines, in marinas, repair shops, and even in private garages. It offers a professional appearance and high-level protection which explains its popularity.

![]()

![]()

![]()

Why use spiral wrap for tubing?

Aside from the obvious protections that we have already mentioned, spiral wrap offers other benefits specifically for tubing that you may not find with other wire management materials. For starters, spiral wrap can prevent from kinking it all types of tubing which is extremely beneficial. Additionally, it can be used to protect pneumatic and hydraulic tubing which many wire management materials cannot protect. Finally, it can help to reduce the risk of accidental holes in tubing caused by abrasion. In this way, spiral wrap is the superior choice when it comes to tubing as well as wire and cable.

What is it made from?

Spiral wrap is made from polyethylene in order to give it flexible strength. That means that spiral wrap is strong enough to protect wires, cables, and hoses while being flexible enough to handle vibration, flux, and other hazards of a marine environment. Choosing the right spiral wrap for your application is not always an easy task. Contact a Pacer expert today and let us help you select the type best suited for your application.

*This page was updated on 6/18/2024*