Categories

- Wire & Cable

- Multi-conductor & Signal Cable

- Battery Cable Assemblies

- Terminals and Connectors

- Electrical Parts

- Electrical Tools

- ID Products

- Wire Management

- Tape & Sealant

- Mounting Panels & Panel Blanks

Need Help?

Click HereGet a Business Account

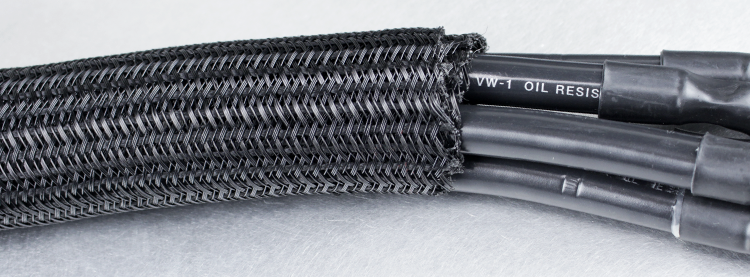

Apply HereWrappable Braided Tubing

What is wrappable braided tubing?

Wrappable braided tubing is a type of wire management material known for its ease of installation and the fact that it eliminates the need for fasteners. The split in the tube allows it to open to handle a wide range of bundling requirements. It rolls out easily and the semi-rigid braid configuration wraps around the entire harness. In this way, all the cables or wires are securely bundled. As a bonus, it is more flexible than spiral wrap or split conduit. Wrappable braided tubing is specifically designed to protect previously installed wires and hoses making it ideal for use in a variety of applications.

"Wrappable braided tubing is specifically designed to protect previously installed wires and hoses making it ideal for use in a variety of applications."

Where are these products implemented?

Wrappable braided tubing is implemented in applications that call for wires and cables to be protected from hazards such as abrasion. Throughout the marine industry it is known due to its simplicity of use and longevity. Wrappable braided tubing is useful in new installations as well as when replacing parts. Say that you have unprotected wires or cables that may be exposed to abrasion. In that case, wrappable braided tubing is a perfect solution. All you will need to get are the proper marine wire and proper battery cable. Since we have covered where these products are implemented, let us look at how you would install wrappable braided tubing.

How do I install it?

Installing wrappable braided tubing is as easy as unwrapping the end of the sleeving and tucking the wire bundle inside. Once there, you would start working the sleeving around the rest of the wire until the entire wire run is enclosed. Wrappable braided tubing has a 25% overlap meaning that it is easy to unwrap while offering a high level of protection. Think about it, if the overlap was 50%, it would be much more difficult to pull apart, hold, and place your wires in. The balance between flexibility and durability makes this type of wire management material the obvious choice for most applications. To make this product even better, wrappable braided tubing is built with installation in tight spaces in mind. This is why it is so flexible.

What benefits and protections does it offer?

Wrappable braided tubing offers a range of benefits and protections such as abrasion resistance, cut resistance, ease of installation, and field serviceability. Additionally, it offers the ability to protect wires, cables, and hoses which is something that most wire management materials cannot do. Wrappable braided tubing is also semi-rigid meaning that while it does offer a decent range of flexibility, it offers a high degree of protection as well. Often times, you will find this type of wire management material in use in applications that call for a combination of all these factors.

Abrasion Protection

![]()

Field Serviceability

Ease of Installation

Where would I use wrappable braided tubing?

Often times wrappable braided tubing is used to protect wire bundles or hoses in areas where high heat or vibration and abrasion are concerns. This is not to say that is all they are designed for. As we said above, this type of wire management material can handle a wide range of conditions and applications. This is why you will find it in use in marinas, repair shops, industrial sites, and even private garages. The bottom line is that you can use wrappable braided tubing in just about any environment that you can think of. Just another reason that wrappable braided tubing is so popular.

![]()

![]()

![]()

What temperature range can it handle?

![]()

Wrappable braided tubing is built to handle temperatures ranging from -94°F to 257°F in most environments. This means that it is suitable for nearly any application where humans can work and even a wide range where they cannot. With this type of temperature range, wrappable braided tubing is the obvious choice for situations where exposure to high levels of heat is a concern. One question that we often hear from manufacturers is about the industries that utilize wrappable braided tubing on a daily basis.

What industries use wrappable braided tubing?

A multitude of industries use wrappable braided tubing including the automotive industry, the marine industry, the transportation industry, and even with databases. This goes to show just how versatile that this product really is. Wrappable braided tubing is the ideal solution for a range of applications that include heat and abrasion as potential concerns. Selecting the correct size of wrappable braided tubing is not always an easy task. Contact a Pacer expert today with any questions that you may have.

![]()

![]()

![]()

![]()

*This page was updated on 2/08/2023*