Categories

- Wire & Cable

- Multi-conductor & Signal Cable

- Battery Cable Assemblies

- Terminals and Connectors

- Electrical Parts

- Electrical Tools

- ID Products

- Wire Management

- Tape & Sealant

- Mounting Panels & Panel Blanks

Need Help?

Click HereGet a Business Account

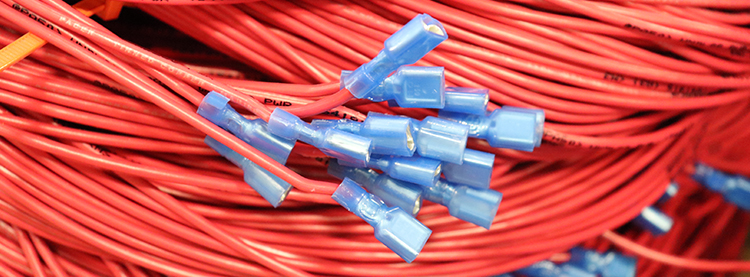

Apply HereDisconnects

What are Disconnects?

Disconnects electrical wire connectors intended to be disconnected and reconnected multiple times. This makes them ideal for use where field serviceability and longevity are potential issues. Disconnect crimp connectors are a great way to protect electrical connections that have to survive in tough environments. Whether dealing with mechanical abuse, wire pull-out, or abrasion, they are a solid choice for long term conductivity. Disconnects are crimp connectors that are sometimes known as quick connects or slip-on connectors. Now that you have a basic idea of what they are, lets look a little more at where they get their name.

"Ring terminals are the most secure type of tongue style terminal available."

Why are they called disconnects?

Disconnects can actually go by quite a few names. The term disconnect comes from the fact that they are designed and built to be "dis-connected" meaning they are not intended to be permanent connections like other types of terminals, such as rings and forks are. That is not to say that they cannot be used as permanent connection methods. You can use disconnect terminal electrical connector types as permanent connections if you choose however, they are designed around the ideas of simplify maintenance and adjustment. With that out of the way, let us look at where these products are implemented.

Where are disconnects implemented?

Disconnects allow for immediate changes to a system

Disconnect terminals are implemented in electrical connections where disconnect-ability and versatility are of the utmost importance. They are perfectly suited for both new installations as well as replacement parts. If you faded terminals or otherwise damaged terminals, then disconnects may just be the solution for you. We also carry all the proper tools and heat shrink that you would need to properly install them. Disconnect terminals are designed with longevity and durability in mind. Now that we have covered some of the basics, let us take a look at what advantages disconnects offer.

What advantages do disconnects offer?

Disconnects are electrical connectors that offer a range of benefits including field serviceability, longevity, durability, and versatility. They are an easy way to achieve connection by fitting the female terminal over the tab of the male terminal. This is due to an indentation on the tongue of the female part which locks with a hole in the male tab. One factor that makes disconnect terminals a solid choice is their holding factor. The holding force found with disconnect terminals is excellent. This is one of the many reasons that disconnect terminals are so widely trusted and used.

Durability

![]()

Versatile

Longevity

What types of disconnects are available?

Pacer carries various types of crimp connectors such as disconnect terminals to meet the widest range of applications possible. Our goal is to offer the most possible solutions so that you can find the exact part that meets your specific needs. We carry piggyback disconnects, fully insulated disconnects, partially insulated disconnects, bullet terminals, non-insulated disconnects, pin terminals, as well as multiple adaptors. Below we will take a brief glance at each of these types of disconnects so that you can choose the one that best fits your applications.

Piggyback

Piggyback

Piggyback disconnect terminals are commonly found in a wide range of settings. They are designed to allow you to connect the male tab to the female opening of another terminal. Our piggyback disconnect terminals carry a male and female connector. The term piggyback refers to the fact that you can connect one tab to the back of another terminal. They are known for their ease of installation long lasting design.

Fully insulated

Fully insulated

Fully insulated disconnects are just what they sound like, fully insulated. That is to say that the entire body of the connector is fully encased in an insulation material leaving very little area for exposure. This type of disconnect offers the highest level of protection as no parts of the connection are left open or exposed whatsoever. Fully insulated disconnect terminals use the same flat tab connection method we mentioned above.

Partially insulated

Partially insulated

Partially insulated disconnect terminals are different from fully insulated in that they do not have any insulation on the connection points of the terminals. They are however insulated on the body where the terminal connects to the wire. This type of terminal is easy to use however they do not provide the same level of rugged protection that one could get with the fully insulated disconnect terminals.

Bullet terminals

Bullet terminals

Bullet terminals are designed as a quick connection and separation method connector. They are built to snap together easily and create a long-lasting connection point if needed. All bullet terminals are fully enclosed when put together however they are not environmentally sealed. Bullet terminals are available in either 22-18 AWG or 16-14 AWG sizes so you can find the type you need to get your job done.

Non-insulated

Non-insulated

Non-insulated disconnects are very similar to both the fully insulated disconnect terminals and the partially insulated disconnect terminals. The main difference being that these terminals do not carry any insulation whatsoever. This makes them more vulnerable to environmental factors than other types of terminals but also makes them perfectly suited to applications in controlled environments.

Disconnects

Disconnects

Disconnect adaptors are similar to piggyback terminals in that they carry both a male and a female side. The main difference with these terminals is that they carry two male tabs and only one female opening. This allows them to connect more terminals than a piggyback terminal could handle. Disconnect adaptors are a simple way to connect two or more terminals to a singular connection point.

Dual disconnect

Dual disconnect

The dual disconnect adaptor is unique for its two-face design. Similar to the disconnect adaptor, the dual disconnect adaptor has two male tabs and one female opening. The difference here is that the dual disconnect adaptor has the two male tabs side by side. This gives the dual disconnect adaptor a unique advantage in that it can handle terminal placement that other types of terminals cannot handle.

Pin terminals

Pin terminals

Pin terminals carry a very small cylinder on the end of the terminal body which is used as the connection point. Pin terminals are primarily used with European terminal blocks and are simple to use and install. All our pin terminals are available in vinyl insulation only and are offered in 22-18 AWG, 16-14 AWG, and 12-10 AWG. Each pin terminal is built to last and has been designed with longevity in mind.

What types of tools should I use with disconnects?

The type of tool to use with disconnect wire connectors varies greatly given the type of disconnect terminal you are using. For example, if you are using the fully insulated disconnects or the partially insulated disconnects then a solid tool would be the VTTR50. If, however, you are using the pin terminals, then you would want to use the VT3120CT. These are not the only tools available, but these two will cover most of the disconnect terminals that we have discussed so far. If you have any questions about which tool to use, contact a Pacer expert. One question we frequently get is about how important using the right insulation really is.

Does the insulation type really matter?

The insulation on a terminal plays a crucial role in how well a connection will perform and how long that connection point may last. Using heat shrink is the best bet as it offers the highest level of protection possible. When the heat shrink is activated, an epoxy lining is melted which then creates an environmental seal. This is why you will find heat shrink terminals used more often than not. Nylon insulation is the next step down. Nylon offers a high level of protection just without the environmental protection. Vinyl is the choice when you need a decent level of protection at an affordable price. Non-insulated is the most cost-effective option available although that comes at the price of higher levels of protection.

Heat Shrink

Nylon

Vinyl

Non-Insulated

What is the difference between bullet terminals and fully or partially insulated disconnects?

Bullet terminals and fully or partially insulated disconnect terminals perform a very similar job however, they do have some distinct differences. Bullet terminals use a round “pin and socket” method connection. This means that the male bullet terminal has a cylindrical protrusion (pin) that snaps into the body of the female bullet terminal (socket). Fully insulated and partially insulated use a flat tab connection method. This means that the male terminal carries a flat protrusion with a hole in the center tab while the female terminal carries a housing to hold that tab. Both of these terminal types perform the same basic task, they create a semi-permanent connection point. They just do it in different ways.

Bullet Terminal

Fully Insulated

Partially Insulated

Why choose Pacer?

Pacer has been a staple of the marine industry for over forty years. We have used that time to build a reputation as an industry leader and a trusted source. Some of the world’s largest boat builders turn to Pacer for their electrical solutions. The bottom line is that you want quality, and quality has always been our focus. When you order from Pacer, you know that you are getting the highest quality possible.

*This page was updated on 2/08/2023*