Related Products

Product Description

| Wire Size | Color | Nylon Part Number | Non-Insulated Part Number |

| 22-18 | Red | TBSN18 | TBS18 |

| 16-14 | Blue | TBSN14 | TBS14 |

| 12-10 | Yellow | TBSN10 | TBS10 |

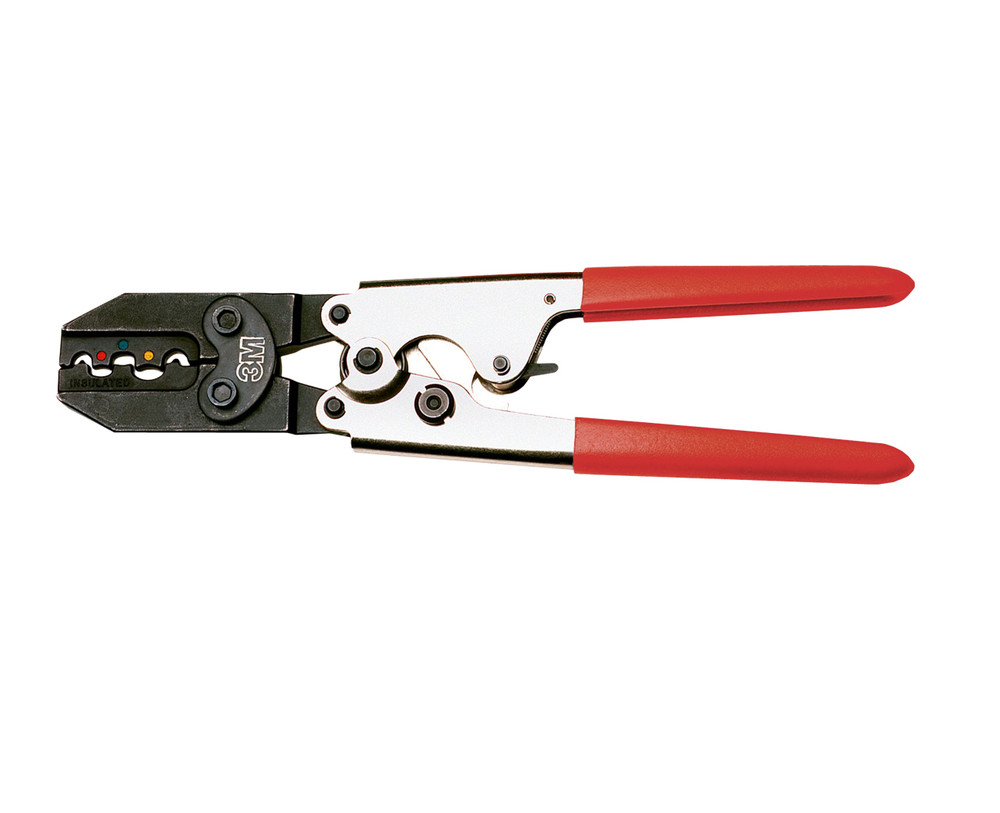

Butt splices are an easy way to create or repair an electrical connection. They are simple to use and built to last. Seamless barrel butt splices come in three varieties of insulation. You can get them in nylon, vinyl or non-insulated. How do you use seamless barrel butt splices? Start by cutting and stripping your wires to the proper length. Now, if you look inside the butt splice you will see an indentation. Your wires should butt up against that. So insert your wire making sure they butt up to the indentation. Crimp using the proper tool. The proper tool guarantees the correct amount of pressure. This ensures a solid connection. Now simply repeat on the other side and you're done.

We would strongly recommend performing a tug test to ensure that the connection is solid. To do this simply grab both wires coming out of the butt splice and give a gently tug. Now you've created a durable connection. Butt splices are used for their rapid installation and durability. Other methods of connection may not offer the same level of protection.

Characteristics:

- Base Material: Copper

- Plating: Tin

Compliances:

- ELV, RoHS compliant

Features:

- Available in non-insulated, nylon insulated, vinyl insulated

- Tin plated copper for corrosion resistance

Product Reviews

Write ReviewThis product hasn't received any reviews yet. Be the first to review this product!