Categories

- Wire & Cable

- Multi-conductor & Signal Cable

- Battery Cable Assemblies

- Terminals and Connectors

- Electrical Parts

- Electrical Tools

- ID Products

- Wire Management

- Tape & Sealant

- Mounting Panels & Panel Blanks

Need Help?

Click HereGet a Business Account

Apply HereWire Ferrules

What are wire ferrules?

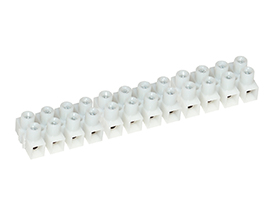

The term wire ferrules refers to types of crimp connectors used on a stranded wire to prevent fraying. Think of them like a barrel that slides over the wires and completely covering them. They are used on wires inserted into IEC (European) style terminal blocks. The purpose is to create a better connection to the block. If you tried to connect the stranded wire to the block the connection would be weaker. This is due to the fraying of the stranded wire. As you tightened the screw, it would push into the stranded wires and cause them to separate. Wire ferrules essentially make the end of the stranded wire one solid piece. This makes these electrical wire connectors a perfect choice for harsh conditions.

"The purpose is to create a better connection to the block."

Where are wire ferrules implemented?

Wire ferrules are implemented in applications that require a stranded wire to become solid wire. They achieve this by encasing the stranded wire in the barrel of the ferrule. When considering electrical connector types make sure to factor where these electrical connectors will live. They are ideal for new installations and equally ideal for replacing parts as well. If you have faded terminals or damaged terminals then wire ferrules may just be the perfect solution for you. All you will need are the proper tools and wire. Now that we covered the basics, let us look at what types are available.

What types of wire ferrules are available?

Wire ferrules are separated by the wire gauges that they handle. In this way, you can find the size you need to handle just about any task. We offer wire ferrule wire connectors in 24-22 AWG, 22-20 AWG, 20-18 AWG, 18 AWG, 16 AWG, 14 AWG, 12 AWG, 10 AWG, 8 AWG, 6 AWG, 4 AWG, and 2 AWG. Each size of wire ferrule carries a specific insulation color making these crimp connectors are easy to identify. Take a look at the table below to help gain a better understanding of which wire ferrule is right for your project.

How do you use a Wire Ferrule?

First, the wire is stripped to the correct length and the ferrule is slid over the exposed wire. The nylon casing at the base of the ferrule should butt up against the insulation of the wire. Next, the wire ferrule is crimped using the proper tool. Proper crimping pressure and technique are key to ensuring continued performance. To enhance the lifespan of the connection, heat shrink can be added for extra protection. At this point, you are set to use the cable as the wire ferrule is fully secure making it a solid choice. Before we move on, we should briefly cover what advantages they offer.

What advantages do they offer?

Wire ferrules offer the advantage of keeping your connections strong when your wire is connected to the terminal block. Not only that, but they also reduce the risk that the wire will pull out. The durable design of wire ferrules ensures that they can not only stand the test of time but that they can handle versatile environments. Wire ferrules are known for their longevity which is just one of the many reasons you will find this type of terminal in use in so many industries.

Durability

![]()

Versatile

Longevity

Where would I use wire ferrules?

Wire ferrules can be used anywhere you are using European terminal blocks or similar applications where you need to prevent wire fraying. That is to say, that they can be used in just about any environment. Often times you will find wire ferrules in use in places like marinas, repair shops, industrial job sites, and even private garages. Since they serve the advantageous purpose of preventing wire fraying, especially when used with terminal blocks, wire ferrules have become known as a versatile and useful product.

What do ferrule boxes include?

Ferrule boxes are convenient packages that contain a variety of wire ferrules in an easily dispensable case. Carrying between 10 to 100 of several different types of wire ferrules, these cases are the ideal solution for field service and on-the-go needs. We currently offer two very different ferrule boxes in order to give you the largest selection possible. Take a look at the chart below to decide which of the boxes has the wire ferrules that you are looking for.

| Kit 1 Contents | (50)20 AWG White. (100)18 AWG Grey, (100)18 AWG Red, (100)16 AWG Black, (50)14 AWG Blue |

| Kit 2 Contents | (50)12 AWG Grey, (20)10 AWG Black, (20)8 AWG Ivory, (10)6 AWG Green |

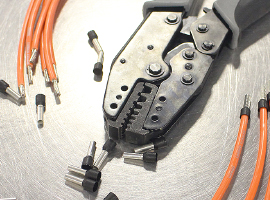

What tools should I use with wire ferrules?

Different size wire ferrules call for different tools in order to get the exact crimp needed. This will ensure a solid connection and a long life even in tough conditions. Pacer offers three ferrule tools to meet just about any need. Each of these tools offers an ability that the other two options do not. We offer the 26-10 AWG side entry wire ferrule tool. As the name suggests, this tool works with 26-10 AWG wire and has six separate crimp nests. Next, we have the 4-2 AWG side wire ferrule tool. With two crimp nests, this tool handles 4-2 AWG wire ferrules which are so large, no other tool can accommodate them. Take a look below and click on the images to be taken to the page to learn more about these durable, long-lasting tools.

When it comes to wire ferrule crimping tools, we employ each of these in our production facilities. That alone should be an indicator as to the quality of these wire ferrule crimping tools. Each is known for its repeatability, reliability, and durability. To be honest, the most useful of all these tools is the 26-10 AWG side entry wire ferrule tool which handles the widest range of wire ferrules possible. Since it handles such a range of ferrules, it is the one our team members reach for the most often. With wire ferrule tools out of the way, let us take a minute and look at why you should choose Pacer.

Why choose Pacer?

With over forty years in the wire and cable industry as well as the marine industry, Pacer has built a name around trust and quality. We have focused on ensuring that every customer gets exactly what they paid for. Serving some of the biggest names in the marine industry as well as everyday boaters has given us a well-rounded view. As the years have gone by, our knowledge base has grown, we have used every opportunity to grow alongside it. We test our products and will not sell them to you if we are unwilling to put them on our own boats. When you see Pacer, you know it means quality.

*This page was updated on 2/08/2023*