Categories

- Wire & Cable

- Multi-conductor & Signal Cable

- Battery Cable Assemblies

- Terminals and Connectors

- Electrical Parts

- Electrical Tools

- ID Products

- Wire Management

- Tape & Sealant

- Mounting Panels & Panel Blanks

Need Help?

Click HereGet a Business Account

Apply HereBoat Cable

![]()

![]()

![]()

![]()

![]()

![]()

![]()

What is boat Cable?

Boat cable is a type of electrical cable designed to be flexible, durable, easy to install, and resistant to the harsh marine environment. Oftentimes, people fail to consider just how hazardous the marine environment can be. The marine environment is subject to more hazards than other environments might experience. These hazards can take the form of exposure to the elements, constant vibration, an increased risk of corrosion, and more. This is why it is essential to use a type of electrical cable designed specifically to handle such an environment.

Another consideration is flexibility. Pacer boat cable is engineered to simplify installations where limited space and sharp turns are concerns. Using a cable that lacks flexibility will make installation a chore, if not impossible. This is why it is important to use Pacer boat cable instead of a different, less flexible, and ultimately less effective type of cable.

"Pacer boat cable is specifically designed to simplify installations where limited space and sharp turns are concerns."

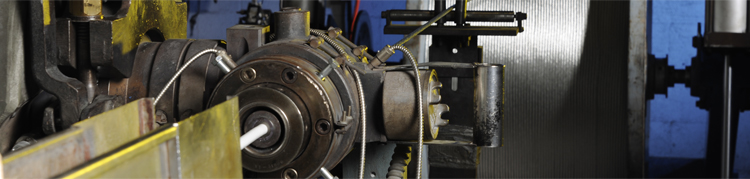

How is it manufactured?

There are several types of boat cable, each manufactured with a specific purpose in mind. All Pacer boat cable is manufactured in Sarasota, Florida, in the United States. Due to the differences in their designs, they are built using vastly different methods. When it comes to Pacer boat cable, there is some overlap as far as the materials are concerned.

We use Type III Class K tinned copper. We choose this particular type of copper and the tinning process for good reason. The copper we use offers high conductivity while the tinning process helps to eliminate the risk of corrosion. All Pacer cable is made from stranded wire, not solid. This is done to increase the flexibility of the cable and reduce the risk of damage to the conductors when the cable is bent.

Finally, all Pacer cable uses proprietary insulation that is made from virgin PVC, never using regrind. Our unique formula allows for high levels of resistance to a variety of hazards and an extreme level of flexibility. After nearly forty years of manufacturing wire and cable, we have refined the process to create the highest quality available.

How flexible is Pacer Boat Cable?

Pacer boat cable is the most flexible available on the market. Installations often occur in areas where there are sharp turns and limited space. Having a boat cable manufactured for flexibility makes these installations faster and more efficient.

As we mentioned above, the insulation is made from a proprietary blend that never uses regrind. Our blend focuses on durability, longevity, and flexibility, and it is easy to tell. You will find that Pacer boat cable is much more flexible than your average everyday boat cable. This is just one of the reasons that you will find Pacer boat cable implemented in so many locations.

What makes the jacket and internal insulation so durable?

In order to survive in a marine environment, our boat cable needs to be highly resistant, flexible, and extremely durable. After over forty years in the wire and cable industry, Pacer has developed a proprietary insulation based around those ideas.

This means that our cable is the best suited to handle the toughest marine environments out there. We spent years perfecting the formula so that it offers the exact attributes we want. To go a step further, we use a talcum powder coating on the internal conductor jackets so that stripping off the outer jacket is easier than ever.

Where is boat cable implemented?

Here we see our boat cable as part of a harness.

All Pacer boat cable is implemented by boat builders, repair shops, and everyday boaters. People use our boat cables to repair and replace parts of their electrical systems as well as to create entirely new electrical systems.

Throughout the marine industry, our duplex boat cable, triplex boat cable, and round boat cable are known for their flexibility and high-level durability. When used with the proper terminals and connectors, our boat cables can be used to create environmentally sealed electrical connections.

What types are available?

The three main types of Pacer boat cable are round boat cable, duplex boat cable, and triplex boat cable, with each being designed to handle a specific purpose. You will find that although they share similarities, each type of boat cable differs greatly from the other types.

In order to get the most efficient electrical system possible, it is important to use the correct type of boat cable for your specific application. Currently, Pacer manufactures over 50 different configurations of UL boat cable in order to meet a variety of needs. Below we'll take a look at what makes these types of boat cables so different from one another.

What is the difference between these different types?

Round Boat Cable

The round shape of this cable allows it to bend in any direction in order to easily route through tight spaces. This is extremely beneficial when working within the confines of a boat interior where space is often limited. Another great feature of this cable is the fact that it can be built with as few as two conductors or as many as twelve.

Duplex Boat Cable

Duplex boat cable is used in everything from simple internal boat wiring to connecting transformers in an AC system. When we manufacture this wire, we extrude the jacket in such a way that there is no space left between conductors. This means no room for moisture to accumulate. The final product is a flexible, durable, easy-to-strip, and easy-to-use duplex boat cable.

Triplex Boat Cable

Triplex boat cable is designed to be used in a range of power-specific applications. There are three different colored jackets that help to indicate the cable's intended purpose. White-jacketed triplex boat cable is used for US 120V AC wiring. Tan jacketed triplex boat cable is used for European 230V AC wiring. Finally, blue-jacketed triplex boat cable is used for US 240V AC wiring. This cable is extruded in the same manner as duplex boat cable.

What kind of conductors does Pacer Boat Cable offer?

Pacer cable carries tinned copper conductors on all of its types of boat cable. This is done for several reasons the most important being that tinned copper prevents corrosion. Now you may think bare copper resists corrosion, and that’s true, to a degree. You see, once we get into marine conditions, corrosion is accelerated, so to speak. That is to say that in wet conditions, corrosion will take hold and spread much faster than in dry conditions.

This is why it is imperative to use tinned copper conductors for all marine applications. Otherwise, you will undoubtedly run into issues surrounding corrosion. If you need to create your own sealed connection points, we have everything that you could need. We offer heat shrink butt splices, closed-end lugs, heat shrink tubing, and all the tools you could possibly need. This way your electrical connections get the protection that they need to provide the power you want.

How many conductors are offered?

Duplex cable offers two conductors, triplex boat cable offers three conductors, and round boat cable offers between 2 and 12 conductors depending on the gauge of the cable.

Below you will find a table that will indicate the gauges and number of conductors that are available.

| Wire Gauge | No. of Conductors | Conductor Colors |

|---|---|---|

| 8 AWG | 4 | Red, White, Black, Green |

| 10 AWG | 2, 3, 4 | Red, Black (2 conductor) White, Black, Green (3 conductor) Red, White, Black, Green (4 conductor) |

| 12 AWG | 2, 3, 4 | Red, Black (2 conductor) White, Black, Green (3 conductor) Red, White, Black, Green (4 conductor) |

| 14 AWG | 2, 3, 4, 6, | Red, Black (2 conductor) White, Black, Green (3 conductor) Red, White, Black, Green (4 conductor) Red, White, Black, Green, Blue, Brown (6 conductor) Red, White, Black, Green, Blue, Yellow, Orange, Grey, Purple (9 conductor) Red, White, Black, Green, Blue, Brown, Yellow, Orange, Grey, Purple, White/Brown, White/Black (12 conductors) |

| 16 AWG | 2, 3, 4, 6 | Red, Black (2 conductor) White, Black, Green (3 conductor) Red, White, Black, Green (4 conductor) Red, White, Black, Green, Blue, Brown (6 conductor) |

| Wire Gauge | No. of Conductors | Jacket Print Color/Conductor Colors |

|---|---|---|

| 6 AWG | 2 | Silver / Red, Black Blue / Red, Yellow |

| 8 AWG | 2 | Silver / Red, Black Blue / Red, Yellow |

| 10 AWG | 2 | Silver / Red, Black Blue / Red, Yellow Black / White, Black |

| 12 AWG | 2 | Silver / Red, Black Blue / Red, Yellow Black / White, Black |

| 14 AWG | 2 | Silver / Red, Black Blue / Red, Yellow Black / White, Black |

| 16 AWG | 2 | Silver / Red, Black Blue / Red, Yellow Black / White, Black |

| 18 AWG | 2 | Silver / Red, Black Blue / Red, Yellow |

| Wire Gauge | No. of Conductors | Jacket Color/Conductor Colors |

|---|---|---|

| 6 AWG | 3 | White / Black, Green, White Tan / Brown, Yellow, Lt. Blue |

| 8 AWG | 3 | White / Black, Green, White Tan / Brown, Yellow, Lt. Blue |

| 10 AWG | 3 | White / Black, Green, White Tan / Brown, Yellow, Lt. Blue Blue / Black, Green, Red |

| 12 AWG | 3 | White / Black, Green, White Tan / Brown, Yellow, Lt. Blue Blue / Black, Green, Red |

| 14 AWG | 3 | White / Black, Green, White Tan / Brown, Yellow, Lt. Blue Blue / Black, Green, Red |

| 16 AWG | 3 | White / Black, Green, White Tan / Brown, Yellow, Lt. Blue |

What resistances does it offer?

All Pacer boat cable offers resistance to acid, alkali, oil, moisture, abrasion, flame, and gasoline. These resistances give the cable an advantage in such a demanding environment. You have to remember that the marine environment will have all of these hazards, not to mention the constant vibration. That is why it is imperative to use a boat cable that has been designed, refined, and manufactured specifically to tackle harsh marine conditions.

![]()

Moisture ![]()

Acid ![]()

Abrasion ![]()

Alkali ![]()

Oil ![]()

Gasoline ![]()

Flame

What compliances does it meet?

Pacer boat cable meets a wide range of compliances and standards. From Underwriters Laboratory to the United States Coast Guard, Pacer strives to exceed standards wherever possible. Below you will find a list of compliances that Pacer boat cable meets or exceeds. If you want to learn more, click on a link to be taken to that particular compliance. If you would like to learn more about compliances or see which Pacer products meet certain compliances, click here.

What industries use Pacer Boat Cable?

The obvious answer here is that the marine industry uses Pacer boat cable, but it goes further than that. The term marine industry implies a vast range of commercial and industrial enterprises. You’ll find Pacer boat cable in large production facilities, repair shops, marinas, and even private garages.

Pacer boat cable is chosen for a variety of reasons. From its flexibility and durability to the fact that it is highly resistant to marine conditions, our boat cable is the preferred choice of some of the world’s largest boat builders. This is why you will find it in so many places. If boat builders trust Pacer Boat Cable to deliver the highest quality marine electrical cable possible, then that is a clear indicator of the level of quality you’ll be getting.

![]()

![]()

![]()

Why Choose Pacer?

With nearly forty years of designing and manufacturing boat cables, we have come to be the experts. Our knowledge and experience have led us to consider aspects that other manufacturers just haven’t thought about. This has led us to create superior boat cables and other products that the competition uses as their template. How else could we become the brand that is trusted by some of the world’s largest boatbuilders? Rest assured that when you see Pacer on your boat cable, you know you’ve got quality.

*This page was updated on 1/30/2025*