What qualities make wire jumpers advantageous?

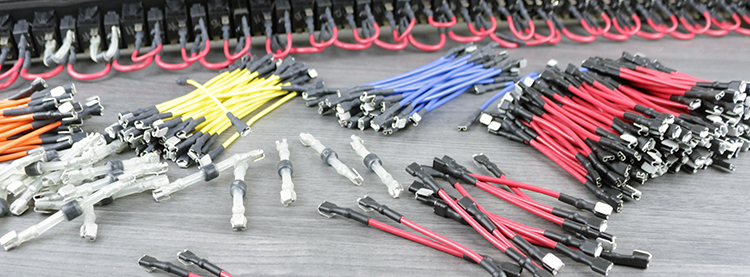

There are multiple qualities that make wire jumpers advantageous. Aside from the highly flexible and durable wire, the proprietary insulation, and the epoxy-lined heat shrink, one of the biggest advantages they offer is convenience. Having to measure, cut, strip, terminate, and heat shrink each jumper is an extremely time-consuming process. Pacer has done all the hard work for you. Now all you need to do is plug them in, and you’re ready to go. As stated above, each wire jumper is very flexible, making bending and twisting a simple process with no damage to the insulation or conductors. Having each wire jumper pre-terminated makes an entire project go faster, especially when the jumpers can have piggyback terminals, which allows for connecting multiple jumpers to a single source. These factors combine to give you the highest-quality wire jumpers available on the market today.

Saves Time

Saves Time

Extremely Flexible

Extremely Flexible

Easy to Install

Easy to Install

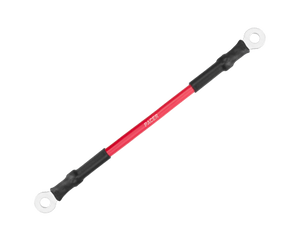

What lengths and colors are available?

Although it varies from style to style, our wire jumpers are available in four-inch or six-inch lengths, making them the ideal size for use on most electrical panels. You can choose from black, red, orange, yellow, and blue insulation. All these options are on top of the variety of terminations you can get on the ends of the wire. This way we offer you the largest amount of choices so that you can get the wire jumpers you need and get the project done.

What gauges are available?

We offer our in-house wire jumpers in either 10-gauge or 14-gauge sizes as well as a specialized diode jumper. Offering the best options without overwhelming you is the ideal way to offer solutions. We have found that time and time again, customers requested the 10-gauge and the 14-gauge which is why we focused our attention on those. This has allowed us to refine these to the point of perfection. You get durability, flexibility, longevity, and high quality all in one package.

Why do wire jumpers carry different terminals on the ends?

No two jobs are alike, and as such, no single terminal will meet the demands of every task. That is why we focused and narrowed the terminals down to just the essentials. You can choose from female disconnect terminals, piggyback terminals, or ring terminals, all of which are the right sizes to fit the common equipment found on the back of marine electrical panels, such as Contura rocker switches.

10 AWG Disconnect Terminal

Piggyback Terminal

Ring Terminal

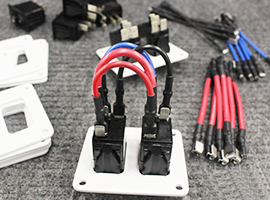

Where are wire jumpers implemented?

Premade jumpers save you from making them yourself.

Wire jumpers are implemented in applications where a panel needs multiple wires in short runs all in close proximity. They are literally designed around the idea of saving time. It would take hours to produce these manually. As we said, they work with panel blanks, breakers, switches, and more. All you need is the proper tools. Now, before you decide which wire jumpers are right for your application, let us take a quick moment to look at diode jumpers just to be clear about their purpose.

Where would I use the diode wire jumper?

Diode wire jumpers are used where you need to control the flow of electric current. They allow the electric current to flow in one direction while blocking it from flowing in the other direction. An important note: if you look at our image below, you will see that the middle of the diode has a black cylinder. On that cylinder, there is a silver ring that indicates which way the current can flow. The silver ring should always face the direction you want the current to flow. All Pacer diode jumpers come with piggyback terminals on each side, allowing them to connect multiple sources and making them a convenient solution.

Why do I need wire jumpers?

You need wire jumpers for the simple reason that they save time by making installing, repairing, maintaining, or replacing your panel or its wiring a much easier task. Our wire jumpers are the perfect lengths for the most common installations. To make it even better, we only use the highest-quality materials possible. This way your wiring is not only done right, but it’s built to last. When you use Pacer wire jumpers, you are taking steps to ensure the longevity of your electrical system even in the face of the harshest marine conditions.

How are these superior to the competition?

Pacer wire jumpers are superior to the competition due to their flexibility, longevity, ease of use, variety of options, proprietary insulation, and their convenience. Many companies may be fine with pushing products out there, but if we won’t use them in our own boats, we won’t sell them to you. The production process has been refined to focus on making these wire jumpers as flexible and durable as possible. The whole point is to give you a solution, not a product. Just like us, you don’t want to have to worry about a part of your boat, especially one that you can’t see. That is why these wire jumpers are focused on surpassing the competition. To give you the highest-quality wire jumpers available on the market.

Are Pacer’s wire jumpers protected against the marine environment?

All Pacer wire jumpers are designed with the harshest marine conditions in mind. This means that each wire jumper uses terminals made from tinned copper and has their connection points covered with epoxy-lined heat shrink. Tinned copper is chosen for its corrosion resistance. Equally, epoxy-lined heat shrink is used as it is the superior protection method for electrical connections. The glue creates a seal that blocks out moisture and eliminates the chance of corrosion setting in.

What compliance do Pacer wire jumpers carry?

Pacer wire jumpers carry a range of compliance from UL to CSA and ABYC. The entire point of having a set of compliances is so that products meet a standard level of quality. But who wants a standard level of quality? No one. That is why these wire jumpers exceed the standards and compliances in the industry. By exceeding those standards, we set the bar higher and give you a superior product. Below you will find a list of compliance's that our wire jumpers meet or exceed. Click on any of the links to be taken to that compliance.

1426 BC-5W2

1015/1230

E-11.15

33 CFR 183.401

Could I make my own wire jumpers?

The answer is yes, but think about all the time and effort it would take to manufacture your own wire jumpers. You would need the wire, terminals, cutting tool, stripping tool, crimping tool, heat shrink, and a heat tool. So you would have to keep all of that inventory on hand. Then you would need to go through each and every step to create them, which would take time that could be spent doing something else. With limited time available each day, don't spend it manufacturing something you can have made by professionals for less than the cost of a cup of coffee.

Can I use them on more than just panels?

Although they are designed to simplify the wiring of panels, wire jumpers can be used in a variety of applications. Some of those applications include use with breakers, single or multiple switches, buttons, and similar pieces of equipment. In this way, you can use wire jumpers to connect pieces of equipment together in less time. The fact that they can be used in multiple applications shows just how useful Pacer’s wire jumpers can be.

Why choose Pacer?

Over the last forty years, Pacer has built a reputation as an industry leader with innovative products and an enormous product catalog. We spent years refining, testing, and perfecting our processes and our products. We are the trusted source some of the world’s largest boat builders turn to for their electrical solutions. When you see Pacer anywhere on your boat, you know you’ve got quality.

*This page was updated on 1/30/2025*

![]()

![]()

![]()

![]()

![]()

![]()

![]()